Improve Efficiency, Regain Lost MW Generation, and Reduce Emissions

Improve Efficiency, Regain Lost MW Generation,

and Reduce Emissions

The SAS Global Total Solutions Approach is designed to have your Coal-Fired Power Operation running at peak performance from the coal yard

through to the boiler.

Coal-fired power plants face challenging operational demands: aging infrastructure, tightening emissions regulations, inconsistent fuel quality, and the need to deliver reliable, efficient baseload power to an increasingly dynamic grid. Even minor inefficiencies in coal flow, pulverizer performance, burner operation, or airflow distribution can increase heat rate, degrade reliability, elevate emissions, and cause lost MW generation.

SAS Global Corporation delivers a Total Solutions Approach—an integrated strategy that improves performance across every major system affecting fuel preparation and combustion. From the coal yard to the burners, SAS provides engineered solutions that restore reliability, improve efficiency, and maximize unit performance.

Click on the specific headings below to learn more:

1. Coal Yard Optimization:

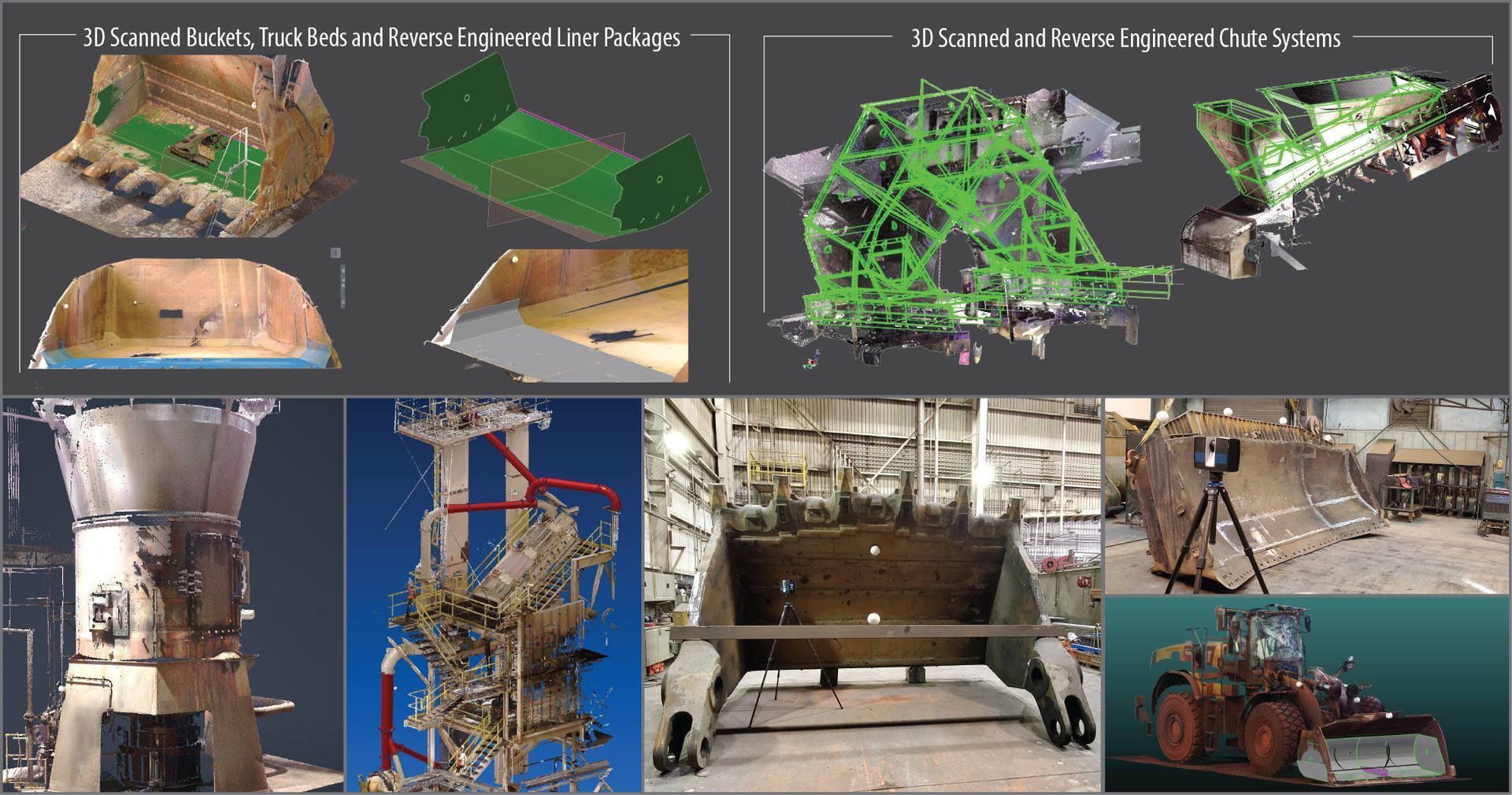

A high-performing combustion system begins long before coal enters the mills. The coal yard is the first, and often the most overlooked stage of the fuel preparation process. Inconsistent flow, material hang-up, improper sizing, excessive spillage, and wear in transfer points all contribute to downstream instability that affects mill loading, fineness, drying capability, and ultimately furnace performance.

The SAS Global Coal Yard Optimization solutions are engineered to eliminate the systemic failures that develop in high-volume material handling operations. Using advanced flow engineering, premium wear materials, and modernized sizing technologies, SAS ensures clean, smooth, and predictable coal delivery from yard to silo.

Why Coal Yard Optimization Matters

If coal does not flow correctly in the yard, the entire fuel system suffers. Typical issues include:

Flow Instability

- Plugging in chute transitions

- Rat-holing or arching over feeder inlets

- Non-uniform discharge patterns

- Inconsistent bunker refill rates

Wear & Material Degradation

- Abrasive wear on liners, walls, and transitions

- Grooving, scalloping, or washboarding in chutes

- Dilution of fuel heating value due to fines accumulation

Sizing & Crushing Issues

- Oversized material causing feeder jams

- Excessive fines reducing mill throughput

- Uneven feed size leading to mill surges and DP spikes

Combustion & Milling Impacts

Coal yard issues cascade into:

- Reduced mill capacity

- Mill damage from tramp materials

A modern coal yard eliminates these problems at the root with engineered flow control and sizing improvements.

Select a Coal Yard Component below to learn more:

Controlled Flow Chutes & Turnkey Coal Handling Systems

Eliminate Plugging • Improve Flow Uniformity • Extend Wear Life

The SAS Controlled Flow Chute is engineered using advanced CFD modeling to create a laminar, predictable material flow pattern that prevents hang-up, reduces dusting, and minimizes wear.

Common Problems with Traditional Chutes:

- Horizontal transitions create dead zones

- Abrupt angle changes cause material impact

- Turbulent flow accelerates liner wear

- Build-up leads to inconsistent feeder loading

- Dust generation creates safety and housekeeping issues

SAS Engineering Advantages:

- Smooth, gradual transitions eliminate turbulent zones

- Coved internal radii prevent material bridging

- Flow surfaces optimized through CFD validation

- Abrasion zones lined with SureAlloy® or RapidFlow®

- Entire systems available as turnkey packages

Resulting Performance Gains:

- Continuous, trouble-free material flow

- No hang-up, even with wet or high-fines coal

- Longer maintenance intervals and reduced outage time

- Lower dust emissions and improved safety

Learn More

Patented Self-Cleaning Coal Sizing Grid System

Increase the Life of Your Crusher • Reduce Crusher Load

• Reduce Crusher Amperage Usage

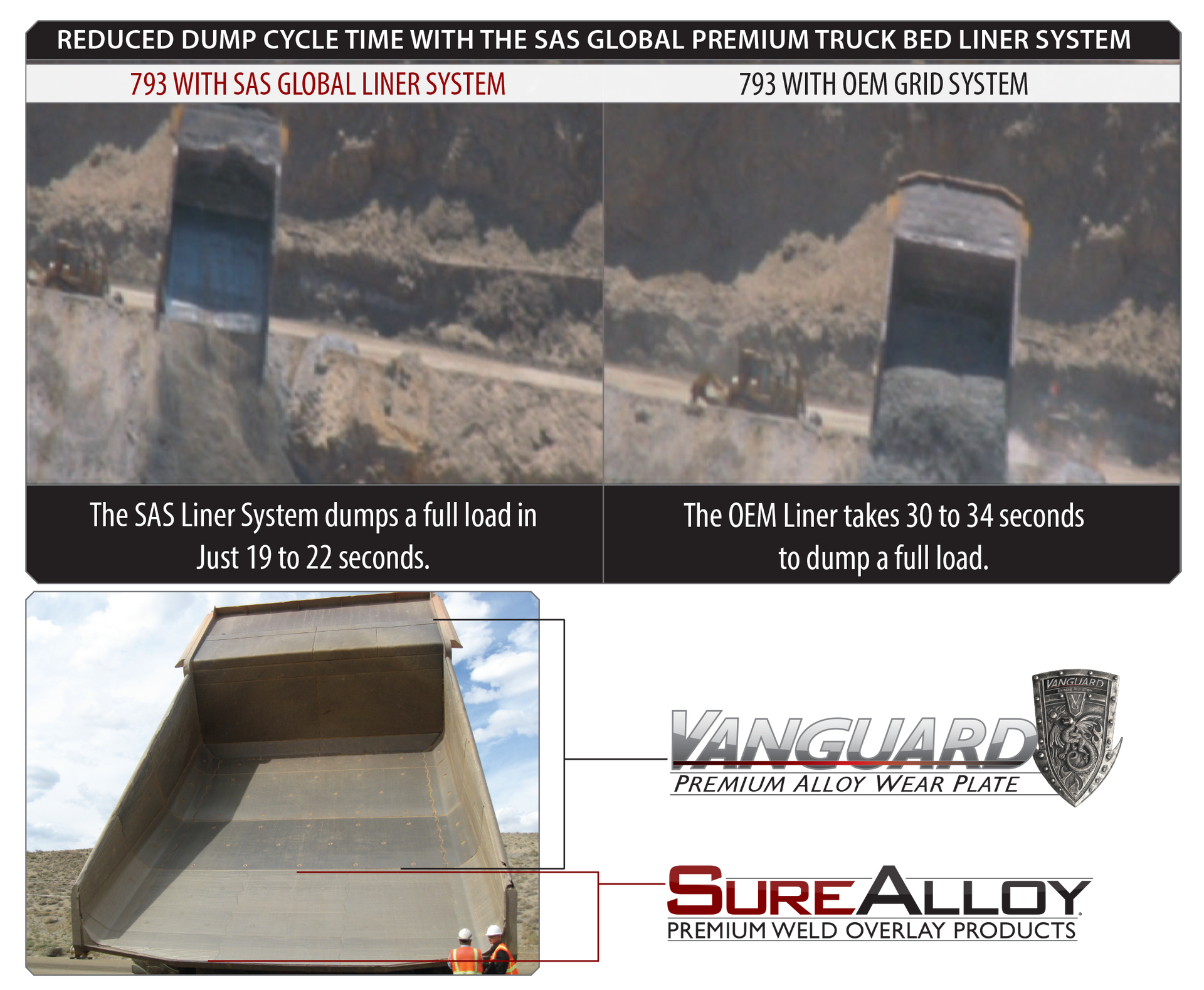

Coal crushing and sizing operations experience constant wear and high energy consumption, as 80-90% of the coal fed through crushers is already at an acceptable size. This unnecessary processing accelerates equipment wear, increases maintenance costs, and consumes excess energy.

The

SAS Patented Self-Cleaning Coal Sizing Grid System is designed to bypass acceptable-sized material before it reaches the crusher, significantly reducing wear, cutting energy consumption, and increasing feed rate capacity.

SAS System Advantages

- Bypasses 60–80% of material that does not require crushing

- Oversized lumps are automatically routed for resizing

- Grid is self-cleaning and designed to prevent clogging

- Significantly reduces wear on crushers and motors

Performance Benefits

- Throughput increased up to 1,200 TPH

- Crusher amperage reduced due to less unnecessary crushing

- Less downtime due to reduced wear and fewer repairs

- Lower operational costs from reduced power consumption

- Higher efficiency in coal processing and material handling

Additional SAS Coal Yard Enhancements

SAS frequently applies the following enhancements as part of a comprehensive yard modernization:

RapidFlow® Premium Smooth Surface Carbide Overlay Chute Liners

- Ultra-smooth, low-friction surfaces

- Designed to minimize material carryback and hangup

- Superior wear life vs. traditional liners

SureAlloy® Carbide Overlay and/or Alloy Wear Steel Liners

- Engineered for extreme abrasion

- Significantly reduce maintenance cycles

- Provide consistent internal chute geometry for years

Turnkey Material Handling Retrofits

Complete retrofit packages include:

- Conveyor Skirt Boxes

- Transfers Chutes

- Diverters Gates

- Transition Chutes

- Controlled Flow Chutes

- Hoppers

This ensures every part of the system is engineered for consistent flow from yard to mill.

System-Level Benefits of SAS Coal Yard Optimization

When the coal yard is modernized, the entire plant benefits:

General Benefits

- Reduce / Eliminate material hangup

- Reduces wear-related failures

- Ensures stable material flow under all conditions

- Reduction in dust

Economic Value

- Fewer forced outages

- Reduced O&M cost

- Higher availability

- Lower auxiliary power consumption

- Better reliability during peak load periods

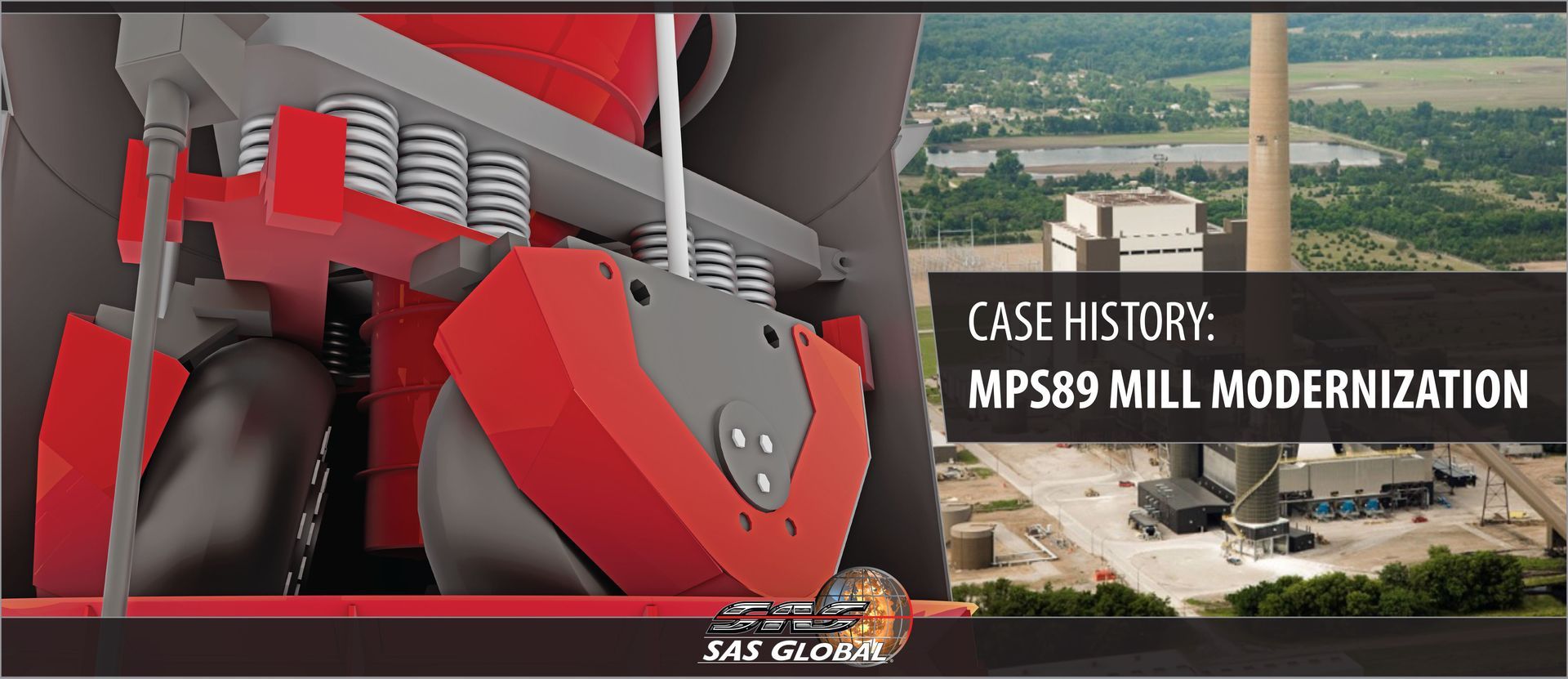

2. Pulverizer Modernization:

Improve Fineness, Balance Fuel Pipes, Increase Capacity, and Restore Mill Reliability

The pulverizer is the heart of the fuel preparation system. Its performance directly determines fineness, drying, fuel distribution, flame stability, LOI, NOx, slagging, and overall furnace heat release patterns. As mills age, component wear, classifier drift, throat deterioration, and grinding profile loss progressively degrade performance.

Even small deficiencies: 5–10% loss in fineness, 15–20% imbalance, or minor throat wear can cause:

- Higher LOI due to incomplete particle burnout

- Elevated CO and localized reducing atmospheres

- Increased NOx from flame instability

- Higher slagging rates on waterwalls

- Loss of drying capacity

- Reduced mill throughput

- Poor low-load operability

- Excessive fan power and increased heat rate

The SAS Global Pulverizer Modernization Program restores and enhances mill performance through engineered upgrades, premium wear materials, patented flow technologies, and modernized classification systems. This approach addresses the root causes of mill performance loss, not just symptoms.

System-Wide Impact of Pulverizer Modernization

When these upgrades are combined, plants see:

Measurable Improvements

- Higher fineness → lower LOI

- Better balance → lower NOx and CO

- Greater capacity → reduced mill trips

- Lower DP → improved fan efficiency

- Stable fuel supply → improved flame stability

- Reduced slagging → better heat transfer & SCR performance

Operational Gains

- Faster startup and improved warm-up curves

- Reduced mill wear and outage time

- Higher reliability during cycling

- Increased asset life and lower O&M costs

SAS pulverizer modernization is one of the highest ROI investments a coal-fired plant can make.

Select a Mill Modernization Component below to learn more:

Rotating Vane Wheel (RVW): Patented

Improve Drying • Reduce Amps • Quicker Mill Response Time

With over 700 vane wheel kits installed across North and South America, SAS Global has a proven track record of success. Many plants that install their first SAS kit quickly schedule full conversions across all remaining mills—a clear sign of the performance and reliability delivered by SAS technology.

Why Power Plants Choose SAS Rotating Vane Wheels

Although each plant has its own unique challenges, the consistent benefits driving these conversions include:

- Improved coal classification and distribution

- Enhanced fineness and combustion efficiency

- Reduced wear and extended service life

- Simplified maintenance with better access to critical components

- Custom-engineered materials matched to your fuel and wear conditions

Performance Benefits

- Lower Mill Motor Amps: Typical reductions have been 10% to 18%

- Lower Primary Air Flows: The SAS design has an adjustable airport, allowing throat air velocities to be adjusted to match the required air mass

- Increased Fuel Drying Capability: The SAS vane/deflector arrangement dries the coal faster by providing a more evenly supported coal bed around the periphery of the bowl.

- Quicker Mill Response Time: An evenly supported coal bed and improved circulation/mixing of hot primary air provides smoother and quicker ramping of the mill.

- Increased Mill Capacity: Having extra capacity is beneficial should a mill be removed from service during peak generation times.

- Lower Maintenance Costs: Even coal flows at lower velocities will improve the life of internal mill components.

High Spin Static Classifier: Patented

Improve Fineness • Increase Fineness Control •

Boost Mill Capacity

The High Spin Static Classifier converts the classifier into a cyclonic separator, increasing centrifugal force and improves fineness performance and mill capacity.

Seamless Adjustments, Manual or Automated

Blade positioning can be adjusted:

- Automatically via actuator for remote control.

- Manually with a single, easy-to-operate lever.

- This flexibility gives operators real-time control over coal fineness to match changing load and fuel conditions.

High Performance Without High Capital Costs

The Adjustable High Spin Static Classifier Retrofit offers a cost-effective alternative to expensive Dynamic Classifier upgrades.

Field-proven results from SAS customers show:

- 6% to 15% capacity improvements

- 99.8% passing 50 mesh

- 76.2% passing 200 mesh

- All achieved while grinding 42 HGI coal

How It Works: Optimized Aerodynamics

The unique blade shape and downward extension are engineered to maximize the kinetic energy and rotational flow generated in the pulverizer’s grinding zone. As circumferentially propelled coal particles enter the classifier, the flow is accelerated into the cone, creating a vacuum effect. This continuously increasing centrifugal acceleration effectively transforms the static classifier into a high-efficiency cyclone separator.

With SAS Global’s High Spin Static Classifier, you get precision control, improved capacity, enhanced fineness—and all without the capital cost of a full Dynamic Classifier retrofit.

Retractable Enhanced Flow Discharge System: Patented

Improve Fineness • Increase Throughput

This innovative system prevents oversized particles from being re-entrained into the classifier.

The traditional Flapper Valve Assembly in MPS and MBF pulverizers has long been a source of operational inefficiency and maintenance headaches. Designed to catch and return rejected coal for regrind, the flapper system often contributes to classifier short-circuiting—allowing coal to recirculate endlessly or stick the flapper door open, disrupting airflow and reducing mill efficiency.

SAS Global’s Patented Retractable Enhanced Flow Discharge eliminates the outdated flapper assembly and its inherent problems—replacing it with a precision-engineered discharge system that improves performance, increases capacity, and simplifies maintenance.

How It Works

The SAS Retractable Enhanced Flow Discharge extends directly into the grinding zone, guiding rejected coal straight to the center of the grinding bowl—right where it’s needed for efficient regrind. This prevents coal from being re-entrained into the classifier airflow, ensuring each particle follows the correct flow path only once.

Field testing has shown: 11-12% improvement in fineness compared to mills with flapper assemblies.

Performance Benefits

- Directs coarse coal back to the grinding zone for faster, more efficient regrind

- Eliminates classifier short-circuiting

- Reduces the number of recirculation cycles through the classifier

- Lowers mill differential pressure

- Reduces mill motor amps

- Increases mill capacity

- Improves fineness for better combustion and lower LOI

Maintenance Advantages

- Retracts easily for fast access to roll wheels

- Simplifies roll wheel oil changes

- Lifts using simple chain falls—no heavy equipment required

- No need to disassemble sections for access

- Replaces unreliable OEM flapper system prone to sticking and failure

SAS Global’s Retractable Enhanced Flow Discharge isn’t just an upgrade—it’s a smarter way to improve mill performance, reduce maintenance, and increase reliability.

Conical Fuel Particulate Diffuser (CFPD): Patent Pending

Balance Fuel Flows • Improve Air-Fuel Ratios •

Improve Combustion • Reduce Emissions

Through extensive modeling, field research, and real-world testing, SAS Global has identified that fuel pipe imbalance must be addressed at the source, as coal exits the pulverizer. Simply adjusting downstream components is not enough. That’s why SAS developed the Conical Fuel Particulate Diffuser, a patented system that optimizes fuel distribution immediately upon exiting the mill, creating a homogeneous air-fuel mixture for superior combustion efficiency.

How the SAS Conical Fuel Particulate Diffuser Works

- Ensures uniform mixing of pulverized coal and air as it exits the upper turret.

- Distributes fuel evenly across all outlet pipes, eliminating imbalances.

- Allows for precise orificing (if needed) to match fuel pipe velocities.

- Reduces NOx, LOI, and unburned carbon, improving boiler efficiency.

Compatible with All Major Pressurized Mill Designs

The SAS Conical Fuel Particulate Diffuser is designed to integrate seamlessly with all types of pressurized mills that use outlet chambers, including:

- MPS Pulverizers

- CE Mills

- MBF Pulverizers

- IHI Mills

- Riley Ball Mill Remote Classifiers

- FW Ball Mill Remote Classifiers

Performance Benefits

- 50–80% reduction in pipe-to-pipe imbalance

- Provides ability to now utilize orifices effectively

- Lower LOI due to more complete particle burnout

- Reduced slagging on lower furnace walls

- Reduction in emissions

CV-Style Adjustable Orifice: Patented

Online Pipe Balancing • Jam-Proof • Precise Velocity Control

Proper fuel pipe balance is essential for equal heat release between burner elevations. The CV-Style Adjustable Orifice provides continuous, repeatable adjustments without mill shutdown.

Common Balancing Problems

- Fixed orifices plug or wear out-of-round

- Improvised orifice plates warp or distort

- Orifice changes require outage time

SAS Engineering Advantages

- Online adjustability with external control mechanism

- Jam-proof design eliminates foreign material hang-up

- Precision-machined adjustment for fine tuning

Performance Benefits

- Perfect fuel distribution achievable (±5% variance)

- Hot burners eliminated

- Lower NOx and LOI due to uniform heat release

- Supports ILD and burner modernization performance

Pre-Riffle Diffuser (PRD): Patented

Balance Fuel Through Your Riffles • Improve Combustion

The SAS Global Patented Pre-Riffle Diffuser is engineered to improve fuel balance through riffles, ensuring even distribution of fuel and air between pipes. By eliminating coal ribboning and creating a homogeneous air-fuel mixture, this advanced diffuser enhances combustion performance, reduces emissions, and improves overall system efficiency.

Key Benefits:

- Balances fuel distribution pipe-to-pipe for improved combustion stability.

- Eliminates coal ribboning, ensuring uniform mixing before entering the riffle housing.

- Enhances air-to-fuel ratio consistency, reducing inefficiencies in fuel delivery.

- Reduces NOx and unburned carbon emissions, supporting environmental compliance.

- Extends burner life by preventing uneven fuel distribution and localized overheating.

How It Works

The SAS Pre-Riffle Diffuser is installed in the vertical section of the fuel piping just below the riffle housing. As fuel and air pass through, the diffuser disrupts ribboning and forces uniform mixing, ensuring that fuel is evenly distributed between both pipes. This prevents imbalances that lead to inefficient combustion and excessive emissions.

Upgrade your fuel distribution system with the SAS Patented Pre-Riffle Diffuser and achieve better fuel balance, improved combustion, and lower emissions.

Other SAS Mill / Pulverizer Components

Extend Life • Reduce Outages • Protect Key Surfaces

SAS provides mill components manufactured from industry-leading wear materials:

- SA1750CR®

- SA2000®

- SA6000®

- Vanguard®

- Ceramic-lined assemblies

Common SAS Wear Components

- Mill wall liners

- Pressure frame wear plates

- Journal liners

- Tire shields

- Mill top liners

- Table and tire/journal hardfacing

Benefits

- 3–10x longer life than OEM materials

- Less downtime

- Extreme abrasion resistance

3. Burner Modernization & Fuel Delivery Improvements:

Restore Combustion Stability, Reduce NOx, Lower LOI, Improve Flame Condition, and Extend Component Life

Burners represent the point where fuel preparation, airflow distribution, and furnace dynamics converge. When burner systems drift out of mechanical tolerance, wear excessively, or suffer from upstream imbalance, the effects cascade through the entire boiler:

- Unstable or oscillating flames

- Skewed heat release patterns

- High NOx formation

- Elevated CO and LOI

- Waterwall tube impingement

- Slagging in burner zones and upper furnace

- Lower turndown capability

- Reduced MW output during load swings

Over time, even slight geometric distortions, pipe wear, or uneven fuel distribution can compound into severe performance losses. SAS Global’s Burner Modernization Suite addresses every major failure mode—fuel distribution, air-to-fuel ratio mixing, geometry, stability, wear, and airflow—to restore original burner performance and often surpass it.

What differentiates SAS from generic rebuilds is that every component is engineered based on field data, CFD validation, advanced metallurgy, and real combustion science, not simply “replacement in kind.”

Select a SAS Burner Technology Below to Learn More:

In-Line Diffuser (ILD): Patented

Homogenize Fuel Distribution • Reduce NOx/CO/LOI • Stabilize Flame Attachment • Correct Roping at Its Source

The SAS ILD is one of the most transformative burner upgrades available. It directly addresses fuel roping, a natural consequence of stratification, sectional wear, classifier imbalance, and long pipe runs.

How Fuel Roping Forms

- Piping system bends and elbows channel fuel into ropes

- Coarse particles migrate outward

- Fine particles concentrate toward the pipe centerline

- Classifier inconsistencies amplify the rope structure

- Roping intensifies right before entering the burner

This rope produces an intensely fuel-rich streak, causing:

- Localized high-temperature zones → increased thermal NOx

- Patchy flame ignition → higher CO

- Incomplete burnout → elevated LOI

- Unstable flame shape and oscillation

- Slagging on waterwalls and burner tiles

In-Line Diffuser Engineered Design

The patented ILD introduces controlled turbulence to the fuel stream that:

- Tear apart the rope’s cohesive structure

- Re-entrain coarse particles into the airstream

- Accelerate mixing without excessive pressure drop

- Produce an even radial fuel distribution at the burner face

This is true homogenization, not simply dispersal.

ILD Performance Advantages

- Eliminates high-density fuel cores responsible for hot burners

- Promotes early ignition → lower CO

- Enhances burnout → lower LOI

- Reduces thermal NOx by removing localized rich zones

- Improves heat release symmetry across the furnace

- Strengthens flame attachment for stability at low load

- Reduces slag formation dramatically

Plants routinely see:

- 30–50% NOx reduction

- 20–60% LOI reduction

- More stable flames during turndown

- Fewer opacity excursions

Two-Piece Burner Nozzle - Corner Fired Series: Patented

The SAS Global Patented (2)Piece T-Fired Burner Nozzle is designed to withstand extreme thermal conditions, preventing sigma phase embrittlement and thermal distortion—common failure points in traditional burner nozzles.

Innovative Two-Piece Design for Thermal Expansion Control

- Independent Expansion & Contraction – The outer and inner housings are not attached, allowing each component to expand and contract freely without creating internal stresses.

- Tapered Fit for Secure Assembly – Precision engineering ensures the inner housing slides smoothly into the outer housing, maintaining structural integrity while allowing thermal movement.

- Locking Tabs for Stability – Prevents forward movement, securing the inner housing in place while enabling natural thermal expansion.

Customizable Material Options for Maximum Service Life

SAS Global offers a range of premium materials for both the outer housing and replaceable tip, allowing customization based on your specific operating conditions.

- Engineered for High-Temperature Applications

- Available in Multiple Alloys for Enhanced Wear Resistance

- Custom Material Selection Based on Fuel Type & Operating Conditions

By upgrading to SAS Global’s Patented (2)Piece T-Fired Burner Nozzle, plants eliminate premature failures, reduce maintenance costs, and achieve long-term reliability in high-temperature combustion environments.

2-Piece Burner Nozzle – Riley Turbo-Fired Series: Patented

SAS Global provides premium burner components designed specifically for Riley Turbo-Fired Burners, ensuring extended wear life, improved combustion efficiency, and simplified maintenance.

Turbo-fired burners run harsh thermal gradients. OEM single-piece nozzles suffer:

- Thermal warping

- Geometry distortion

- Stress fracturing

- Misalignment

- Slag accumulation on deformed surfaces

These distortions compromise air/fuel mixing and flame shape.

SAS Patented Two-Piece Solution

- Inner and outer housings expand independently

- Nozzle maintains axial alignment

- Manufactured with heat and abrasion resistant materials

- Mechanical locking generates a precise, repeatable installation

- No internal welds between inner and outer housing → no stress points → no failures

Operational Benefits

- Maintains consistent flame profile

- No failure from sigma phase and thermal distortion

- Increases service life 2–4× vs. OEM

- Easy tip replacement from inside of the boiler

Other SAS Riley Turbo-Fired Burner Components

High-Performance Piping & Elbows

- Fabricated from SureAlloy® Premium Carbide Overlay Plate for an exceptionally long service life.

Streamlined Pant-Leg Transition

- Constructed from SureAlloy® Premium Carbide Overlay for superior durability.

- Premium Flow Splitter – Hardfaced with SureAlloy® and designed to rotate, doubling its service life.

- Easily replaceable without damaging the pant-leg structure, reducing downtime.

Burner Transitions

- Built with SureAlloy® Premium Carbide Overlay, ensuring extended service life.

Premium Burner Barrels

- Available in Stainless Steel and SureAlloy® Premium Carbide Overlay Plate for maximum wear resistance.

Tilting Nozzle Tips

- Available with SAS Patented Two-Piece Nozzle Design for quick and easy replacement.

- Splitter plates are easily replaceable, reducing maintenance costs and downtime.

SAS Patented In-Line Diffuser System

- Designed to mix air and coal into a homogeneous mixture just before entering the boiler.

- Each system includes three (3) Patented In-Line Diffusers to ensure optimal combustion efficiency.

SAS Wall-Fired Burner Technology & Components

Engineered for Superior Combustion • Extended Service Life • Simplified Maintenance

SAS Global provides high-performance Wall-Fired Burner Components and Replacement Parts designed to improve combustion efficiency, enhance durability, and reduce maintenance requirements. Fabricated from premium wear-resistant materials, these components ensure long-lasting reliability in high-temperature, high-wear environments.

Key Benefits:

- Optimized Combustion – Precision-engineered components improve fuel-air mixing, enhancing burner stability and efficiency.

- Extended Service Life – Premium materials withstand extreme heat, abrasion, and corrosion, reducing downtime.

- Reduced Maintenance – Engineered for easy installation and long-term durability, minimizing operational disruptions.

SAS Global Wall-Fired Burner Components:

- Burner Barrel Tubes – Built for durability and high-temperature resistance.

- Flame Regulators – Ensure stable, controlled combustion.

- Flame Regulator Tube Protection – Shields critical burner components from excessive wear.

- Flame Stabilizers – Improve flame shape and burner performance.

- Flat Back Elbows – Precision-fabricated for long-term reliability.

By upgrading to SAS Global Wall-Fired Burner Modernization Components, power plants can maximize efficiency, lower emissions, and extend burner lifespan—ensuring long-term operational success.

SAS AirJet Burner Modernization

Upgrade Legacy Designs with Premium Wear-Resistant Materials for Maximum Uptime, Thermal Integrity, and Maintenance Savings

Transform your old ceramic-lined or stainless-steel burner barrels into long-life, low-maintenance performers with SAS Global’s modernized Airjet Burner Barrel Assemblies. Backed by over 70 years of wear-resistant engineering expertise and trusted by the power generation industry, SAS upgrades are designed to eliminate chronic failure points, reduce downtime, and improve combustion reliability.

Our enhanced design features superior metallurgy and proprietary SureAlloy® materials, offering dramatically improved wear life and thermal resilience in demanding operating environments.

Engineered for Thermal Stability and Lasting Performance:

- No Tip Warping or Distortion: The front nozzle sections of both barrels are fabricated from Spuncast HN Stainless Steel, ensuring they maintain shape under extreme heat and resist warping during high-load thermal cycling

- No Tile Debonding or Delamination: Our SA6000® inlet deflector cone eliminates failures common to ceramic-lined designs—no risk of tiles cracking, falling off, or causing downstream damage

- Thermal Shock Resilient: Built with superior overlay and alloy materials to withstand repeated cold starts, cycling, and extended high-temp exposure

What You Get with an SAS Modernization:

- Extended Service Life – Reduced failure risk with advanced carbide overlays and heat-resistant alloys

- Lower Maintenance Costs – Less frequent changeouts, fewer outages, and simplified serviceability

- Superior Material Integrity – Eliminates cracking and delamination common in ceramic linings

- Improved Burner Performance – Uniform combustion, consistent airflow, and reduced slag buildup

Built for Power Plants That Demand More:

SAS’s Airjet Burner modernization program is field-proven to outperform OEM designs in coal, biomass, and multi-fuel applications. Customers report longer operational intervals, improved heat profiles, and reduced unplanned maintenance events.

Why SAS AirJet Burner Components?

- No warping or thermal distortion

- Eliminates failure-prone ceramic linings

- Consistent combustion performance

- Lower lifecycle cost and fewer outages

- Ready-to-install retrofit design

- ISO-compliant, QA/QC-verified designs

Stop replacing the same failed parts. Upgrade to SAS-engineered reliability.

SAS Abrasion Resistant Fuel Piping

Extended Service Life • Fabricated or Hardfaced with Premium Wear Resistant Materials

SAS Global specializes in high-performance abrasion-resistant piping systems, ensuring long-lasting reliability in high-wear applications. SAS Global fabricates piping from SureAlloy Premium Carbide Overlay Plate, or clads the inner diameter of an existing pipe with hardfacing (CladPipe), providing unmatched wear resistance and superior performance.

Why Choose SAS Global Piping Solutions?

- Utilizes Premium SAS Abrasion-Resistant Materials – Ensuring the highest quality and longest service life.

- Custom Fabrication for Any Application – From straight pipes and elbows to complete fuel piping systems.

- Engineered for High-Wear Environments – Built to withstand extreme abrasion and erosion.

- Reduces Maintenance & Downtime – Extended service life means fewer replacements and lower costs.

Comprehensive Piping Solutions

- Single Straight Pipes & Elbows – Precision-fabricated for seamless integration.

- Complete Fuel Piping Systems – Custom-engineered solutions tailored to your plant’s specifications.

- Complex Piping Configurations – Designed for high-efficiency material handling in the toughest conditions.

By upgrading to SAS Global Abrasion-Resistant Piping, plants benefit from:

- Extended pipe life, reducing replacement frequency.

- Improved efficiency with optimized material flow.

- Minimized downtime due to wear and failures.

Upgrade your piping systems with SAS Global’s abrasion-resistant solutions—engineered for durability, efficiency, and long-term performance.

Combined Burner & Fuel Delivery Modernization Impact

When ILDs, upgraded nozzles, stabilizers, barrel tubes, modern elbows, and SAS fuel piping are combined:

Plants Experience Transformational Gains

- 10–50% reduction in NOx

- 20–60% reduction in LOI

- Major reductions in CO spikes

- Extremely stable flame envelopes

- Significant reduction in slagging

- Lower excess air requirements → improved heat rate

- Increased unit turndown range

- More robust MW stability during rapid load swings

- Dramatically reduced burner maintenance intervals

This suite offers one of the highest ROI modernization investments available for coal-fired units.

4. Diagnostic Testing:

Data-Driven Root-Cause Identification for Maximum Performance Improvement

Modern coal-fired power plants cannot rely on assumptions or generic tuning. Achieving stable, efficient, low-emission combustion requires accurate diagnostics that identify the true sources of imbalance. SAS Global provides the most comprehensive diagnostic testing program in the industry, combining advanced analytical tools, experienced engineers, and proven field methodologies.

Diagnostic work is performed both “inside the mill system” and “inside the furnace,” giving SAS the ability to trace problems across the entire fuel and air path.

Advanced Measurement Capabilities

SAS engineers use the industry’s most comprehensive suite of diagnostic tools to evaluate every stage of the fuel and air path—from the mill outlets to the burner tips and into the furnace. The objective is to obtain precise, data-driven insights that eliminate guesswork and allow targeted, high-impact performance improvements.

Each diagnostic test is engineered to uncover a specific class of performance issues, whether mechanical, aerodynamic, thermal, or combustion-related. Together, these tests provide a complete picture of system behavior and help SAS develop optimized solutions for fineness, balance, emissions, and efficiency.

Why Testing Is Mission-Critical

Accurate diagnostics allow SAS to:

- Pinpoint the exact causes of performance loss

- Design precise, high-ROI modernization plans

- Validate improvements with data

- Provide long-term, sustainable performance gains

Testing is the backbone of SAS’s Total Solutions Approach—and the reason SAS upgrades consistently deliver measurable, repeatable improvements in MW output, heat rate, and emissions.

ACFM Measurement Isokinetic Fuel Flow Testing

Purpose: Quantifies coal distribution between burner lines by drawing fuel samples at velocity-matched (isokinetic) conditions.

What It Detects

- Fuel-rich or fuel-starved fuel pipes exiting the mill

- Classifier Issues

- Coal “roping” effects

- Excessive or insufficient primary air (PA)

- False air leakage

Engineering Importance

Isokinetic testing is the most accurate method of determining burner-to-burner imbalance—data that directly affects NOx, LOI, CO, and flame quality.

Impact

- Identifies root causes of hot burners and high NOx

- Dictates balancing strategy for orifices, PRDs, or ILDs

- Provides baseline reference for all tuning and modernization work

Fuel Fineness Analysis (Mill Performance Diagnostics)

Evaluates the particle size distribution leaving each pulverizer.

What It Detects

- Grinding roll wear or poor adjustments

- Classifier inefficiency

- Incorrect grinding pressure or throat clearances

- High reject rates and coarse particle carryover

Engineering Importance

Coarse fuel particles:

- Burn slower

- Create reducing atmospheres at burner exits

- Increase LOI

- Raise slagging probability

- Limit capacity & increase heat rate

Impact

- Guides mill modernization strategy

- Validates performance of classifiers, RVWs, and discharge systems

- Predicts downstream burner performance

HVT (High Velocity Temperature) Furnace Mapping

Creates a 3D temperature profile across multiple furnace elevations by inserting high-temperature probes directly into the flame envelope.

What It Detects

- Hot spots and cold spots across the furnace width

- Poor burner-to-burner flame alignment

- Asymmetric heat release

- Slagging-prone areas and tube overheating zones

- Combustion instability during turndown

Engineering Importance

Temperature asymmetry is a primary cause of:

- Waterwall wastage

- Slag buildup

- SCR catalyst poisoning

- Furnace vibration

- Performance degradation

Impact

- Enables targeted burner tuning

- Supports mill/burner balancing strategy

- Reduces slagging and tube metal temperatures

Multi-Point Flue Gas Sampling (Combustion Completeness Diagnostics)

Measures NOx, CO, CO₂, O₂, SO₂, and other combustion gases at different furnace elevations and burner rows.

What It Detects

- Over- or under-stoichiometric zones

- Poor air/fuel mixing leaving burners

- Incomplete combustion events

- CO hang-up zones

- NOx formation patterns

- Effects of OFA placement or incorrect staging

Engineering Importance

Gas sampling tells the truth of combustion completeness and is essential for emissions reduction, fuel savings, and improved heat rate.

Impact

- Identifies where tuning will deliver the most benefit

- Confirms the effectiveness of ILDs, PRDs, and classifier improvements

- Ensures furnace staging supports regulatory compliance

Burner Line Velocity / Balance Profiling

Measures the velocity of the air/fuel mixture balance in each burner pipe.

What It Detects

- Pipe wear and geometry distortion

- Inconsistent air velocity between burner lines

- Poorly performing orifices

- Malfunctioning classifier or RVW effects

- Improper coal entrainment or dropout zones

Engineering Importance

Velocity determines:

- Particle suspension quality

- Residence time within flame envelope

- Early ignition behavior

- Fuel distribution consistency

Impact

- Identifies need for corrective piping, orifices, or ILDs

- Enables alignment of fuel delivery prior to tuning

- Stabilizes flame patterns at all loads

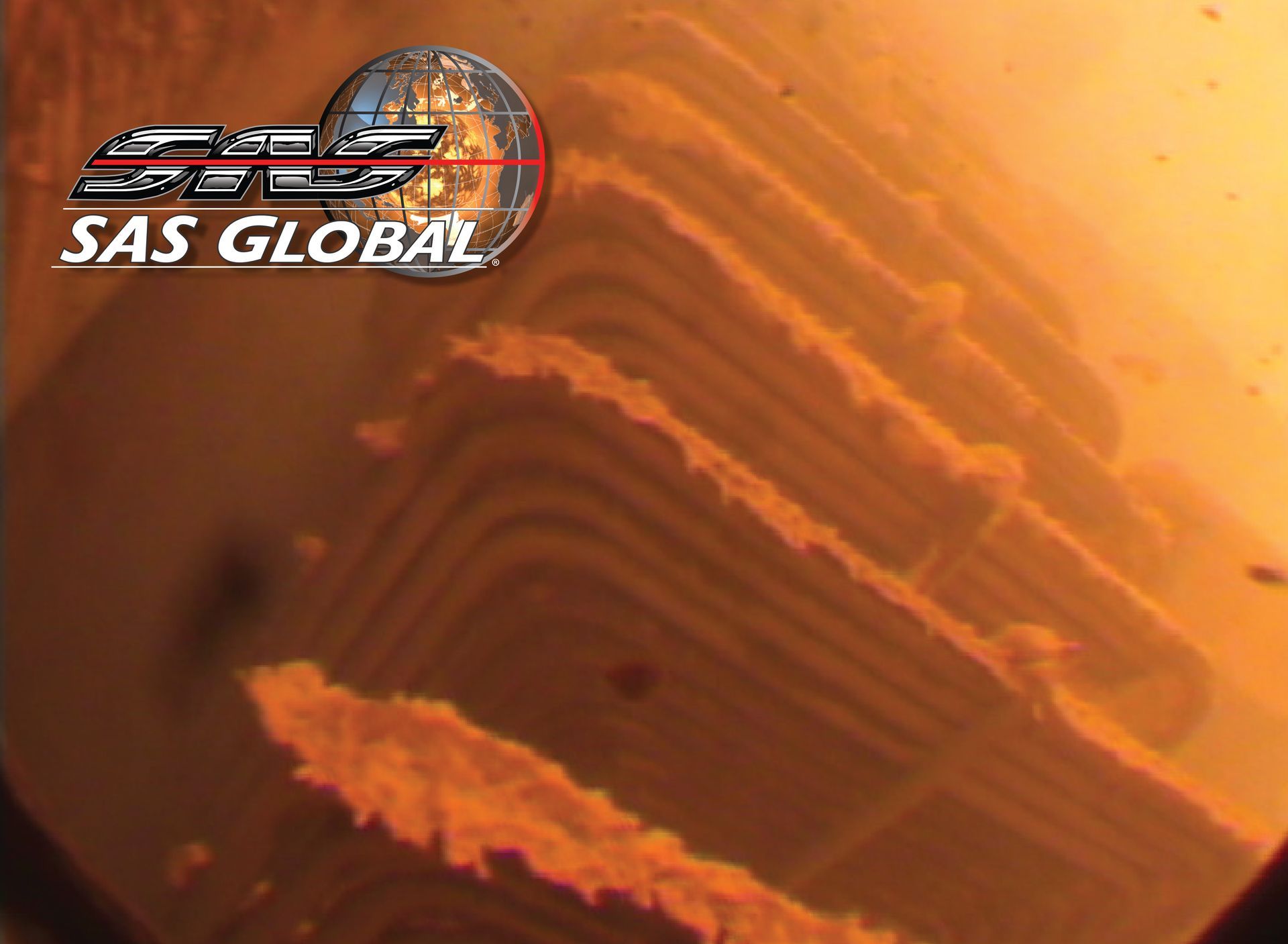

High-Temperature Flame Video (Real-Time Combustion Behavior Analysis)

Visual inspection inside the burner throat using high-temperature cameras.

What It Detects

- Flame length, width, and shape

- Flame oscillation and pulsation

- Ignition stability

- Flame attachment to burner throat

- Wall impingement and near-wall reducing zones

- Slag formation patterns

Engineering Importance

Flame video provides immediate, intuitive insight that complements quantitative data—allowing engineers to visualize the success (or failure) of combustion improvements.

Impact

- Identifies flame instability early

- Confirms burner modernization effectiveness

- Reveals causes of slag, tube wear, and NOx spikes

5. Combustion Optimization:

Lower Emissions, Improve Heat Rate, and Restore MW Output

SAS Global’s combustion optimization program is built around a mobile, real-time testing and tuning laboratory staffed by seasoned combustion engineers. Unlike generic tuning approaches, SAS uses data from diagnostics, combined with patented burner and mill technologies, to deliver measurable, reliable improvements in every aspect of furnace performance.

What SAS Combustion Optimization Includes

Burner Air Zone Alignment

- Correcting airflow distribution within each burner (inner, outer, secondary, and tertiary air zones) restores flame symmetry and dramatically reduces NOx and CO.

OFA (Overfire Air) System Optimization

- Properly tuned OFA reduces thermal NOx formation while preserving ignition stability. SAS optimizes OFA volume, direction, velocity, and mixing penetration.

Mill and Classifier Operating Adjustments

- Adjusting throat pressure, classifier settings, grinding force, or vane positions improves fineness, drying, and capacity without sacrificing reliability.

Windbox, Damper, and Register Tuning

- Optimized windbox performance yields better velocity control, flame shape, and furnace heat release uniformity.

Primary Air (PA) to Fuel Ratio Optimization

- Correct PA ratio ensures early ignition, full particle burnout, lower LOI, and improved heat rate.

Low-Load Stability Tuning

- SAS helps plants increase turndown capability, stabilize flames at minimum load, and reduce low-load CO excursions.

Documented Results

- 15–50% NOx reduction without major capital investment

- Lower CO across all elevation sets

- LOI reductions (20–60%) through more complete fuel burnout

- Greater MW stability during load swings

- Heat rate improvements from reduced excess air and slagging

- Cleaner boiler surfaces → fewer sootblowing cycles

SAS combustion optimization does not simply “tune the burners”—it transforms the furnace into a stable, efficient, low-emission heat release system.

6. MATS & HAPs Compliance Support:

Combustion-Based Solutions for Cleaner Operation

Meeting Mercury and Air Toxics Standards (MATS) and Hazardous Air Pollutant (HAPs) regulations requires more than add-on control technologies. Many compliance barriers originate from incomplete combustion, poor fineness, and fuel imbalance—issues SAS specializes in correcting.

How SAS Supports Compliance

Reduced LOI for ESP and Baghouse Efficiency

- High LOI reduces particulate collection efficiency and increases mercury re-emission. Improving fineness and combustion completeness dramatically strengthens downstream capture.

Improved Coal Fineness Reduces Mercury Re-Emission

- Fine, evenly distributed particles burn more completely, reducing carbon “sponge” surfaces that re-emit mercury during cooling.

More Stable Combustion Reduces Dioxins, Furans & Metals

- Uniform flame shape and balanced heat release eliminate localized high-temperature zones where hazardous pollutants thrive.

Slagging Reduction Improves SCR, ACI & Baghouse Performance

- Cleaner heat-transfer surfaces and more stable furnace conditions increase efficiency of downstream control technologies.

Consistent Air/Fuel Ratio Improves Overall Emissions Profile

- NOx, CO, VOCs, PM, and HAPs all decrease when combustion is uniform and complete.

Bottom Line

SAS enables compliance by fixing combustion at its source—not by relying solely on expensive after-treatment systems.

7. Regain Lost MW Generation:

Unlock Hidden Capacity Across the Fuel & Air Path

Most coal-fired units today operate below original design capability, not because of generation limits, but because of accumulated inefficiencies that reduce combustion quality, heat rate, and fuel throughput.

SAS specializes in identifying and removing these restrictions.

Where Lost MW Is Hiding

Poor Coal Flow Distribution

- Fuel-rich burners limit upper load capability due to flame instability.

Restricted or Worn Fuel Piping

- Causes velocity drop, coal dropout, and unstable flame patterns that require operators to back down load.

Low Fineness & High Reject Rates

- Coarse coal increases carbon burnout time and reduces thermal efficiency.

Slagging & Fouling

- Slag reduces furnace heat transfer, increases exit gas temperature, and forces derates to protect SCRs and air heaters.

High Excess Air Requirements

- Plants running 5–10% more excess air than needed lose massive quantities of useful heat, lowering MW output and increasing heat rate.

Instability at Low Load

- Units unable to maintain stable burner operation cannot safely swing load for grid support.

What SAS Typically Recovers

Most plants experience 5–25 MW in regained capacity after SAS modernization—often without major capital investment.

Why MW Recovery Matters

- Increased dispatch priority

- Greater operational flexibility

- Lower cost per MWh

- Higher plant revenue

SAS modernization does more than improve emissions—it restores a plant’s competitive edge.

The SAS Advantage:

Integrated Engineering, Premium Materials, Patented Technologies & Turnkey Field Expertise

SAS Global’s value lies not just in individual products, but in the integration of engineering, metallurgy, manufacturing, and field execution—all under one roof. This vertical integration creates a level of consistency and reliability unmatched in the industry.

What Sets SAS Apart

Advanced Engineering & CFD Modeling

- SAS engineers model coal flow, air distribution, mill performance, and furnace dynamics to design system-level improvements—not just component replacements.

Premium Wear Materials Manufactured In-House

- SureAlloy®, SA2000®, SA6000®, and RapidFlow® carbide overlays deliver unmatched wear life, drastically extending component longevity.

Precision Fabrication & Machining

- Burner nozzles, fuel pipe elbows, classifiers, and mill components are built to exact tolerances for consistent, reliable operation.

Patented Modernization Technologies

- SAS holds numerous patents—including the ILD, PRD, CFPD, and Retractable Enhanced Flow Discharge System—each solving critical operational problems.

Experienced Field Installation Teams

- SAS field crews specialize in mill installation, burner upgrades, fuel piping replacements, and turnkey system retrofits—executed safely, efficiently, and on schedule.

Comprehensive Diagnostic & Tuning Services

- From isokinetic testing to full furnace optimization, SAS ensures every system functions as an integrated whole.

One Partner — Complete Responsibility

- SAS manages engineering, fabrication, delivery, installation, testing, and tuning.

- No multiple vendors.

- No misaligned scopes.

- No finger-pointing.

The Result

- Maximum performance.

- Minimum downtime.

- Reliable, repeatable, measurable improvements.

SAS Global’s Total Solutions Approach improves every stage of the fuel cycle—enhancing reliability, lowering emissions, increasing efficiency, and regaining MW output. Whether upgrading mills, burners, coal piping, or conducting systemwide optimization, SAS delivers measurable performance gains that directly impact plant profitability and operational compliance.

Modern coal-fired units can still operate cleanly, efficiently, and reliably—but only when the fuel system is modernized and optimized end-to-end. SAS Global’s integrated engineering solutions, advanced wear materials, patented technologies, and field expertise empower plants to reduce emissions, improve heat rate, and capture lost MW generation. From the coal yard through the boiler, SAS provides a comprehensive path to peak performance and long-term operational success.