The Critical Role of MATS and HAPs Testing in Coal-Fired Power Plants

The Critical Role of MATS and HAPs Testing

in Coal-Fired Power Plants

Ensuring Compliance, Efficiency, and Environmental Stewardship

In today’s regulatory environment, compliance isn’t optional; it’s essential. For coal- and oil-fired Electric Generating Units (EGUs) with capacities over 25 megawatts, the Mercury and Air Toxics Standards (MATS) and Hazardous Air Pollutants (HAPs) regulations established by the U.S. Environmental Protection Agency (EPA) set strict emission limits on mercury, acid gases, dioxins/furans, and other toxic pollutants.

These standards, governed under the National Emission Standards for Hazardous Air Pollutants (NESHAP) and the Maximum Achievable Control Technology (MACT) framework, level the playing field by requiring both new and existing plants to meet the same stringent emissions performance as the best-controlled units in operation.

Why MATS and HAPs Testing Matters

Coal-fired power plants produce a variety of toxic byproducts during combustion. Mercury, non-mercury metals, acid gases, and dioxins/furans all pose environmental and operational challenges. Without ongoing testing and optimization, these emissions can rise above permitted thresholds, exposing plants to costly violations and efficiency losses.

Regular

MATS and

HAPs testing helps ensure:

- Regulatory compliance with federal emission limits.

- Improved combustion performance through balanced fuel and air distribution.

- Reduced boiler slagging and fouling, lowering maintenance costs.

- Optimized heat rate and efficiency, improving overall plant output.

- Extended equipment life through reduced wear on pulverizers, burners, and scrubbers.

Many power plants in the U.S. are over 50 years old, and aging equipment can cause performance drift over time. Routine emissions testing and combustion tuning not only bring these systems back into compliance but also help modernize the unit’s performance profile.

Control Technologies and Work Practice Standards

EPA’s guidelines identify several proven technologies for reducing air toxics emissions, including:

- Selective Catalytic Reduction (SCR) and Flue Gas Desulfurization (FGD) for mercury and acid gases.

- Activated Carbon Injection (ACI) with Fabric Filters (FF) or Electrostatic Precipitators (ESP) for fine particulate and mercury control.

- Dry Sorbent Injection (DSI) for acid gases.

- Routine inspection and maintenance protocols to minimize dioxin and furan formation.

The SAS Global Combustion Optimization & Testing Group supports these efforts with both services and patented combustion technologies that ensure your plant not only meets, but exceeds, federal emission expectations.

How SAS Global Supports MATS and HAPs Compliance

SAS Global Corporation has decades of experience helping coal-fired utilities maintain compliance while improving overall performance. Our Combustion Tuning Group offers full-service MATS and HAPs compliance testing with advanced diagnostics and field engineering support.

Our comprehensive capabilities include:

- Compliance Testing & Inspection Programs

- Boiler and Combustion Tuning

- Overfire and Secondary Air Optimization

- Backpass Emissions Mapping

- Burner and Flame Inspections

- Airflow Measurement & Calibration

- Pulverizer Inspections and Tuning

- Patented Pulverizer and Combustion Components

- Detailed Baseline and Tuning Reports

Unlike generic test contractors,

SAS delivers a total system solution, combining combustion tuning with our

high-performance engineered components. This integrated approach not only ensures regulatory compliance but also:

- Reduces NOx, CO, and O₂ emissions.

- Improves heat rate and combustion efficiency.

- Increases mill capacity and coal fineness.

- Reduces scrubber catalyst consumption.

- Extends component life and reduces maintenance downtime.

- Provides a rapid ROI through fuel savings and extended service life components.

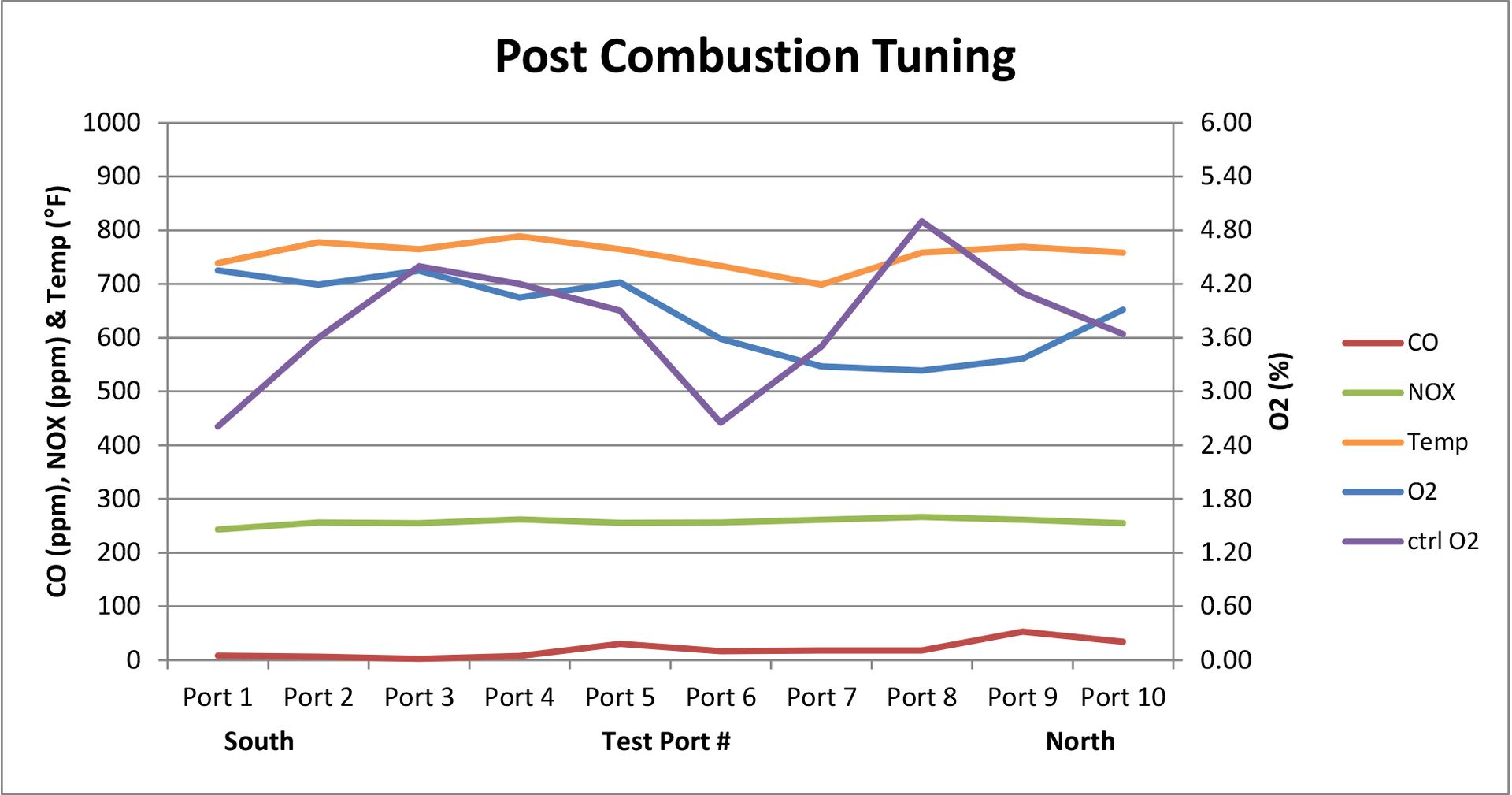

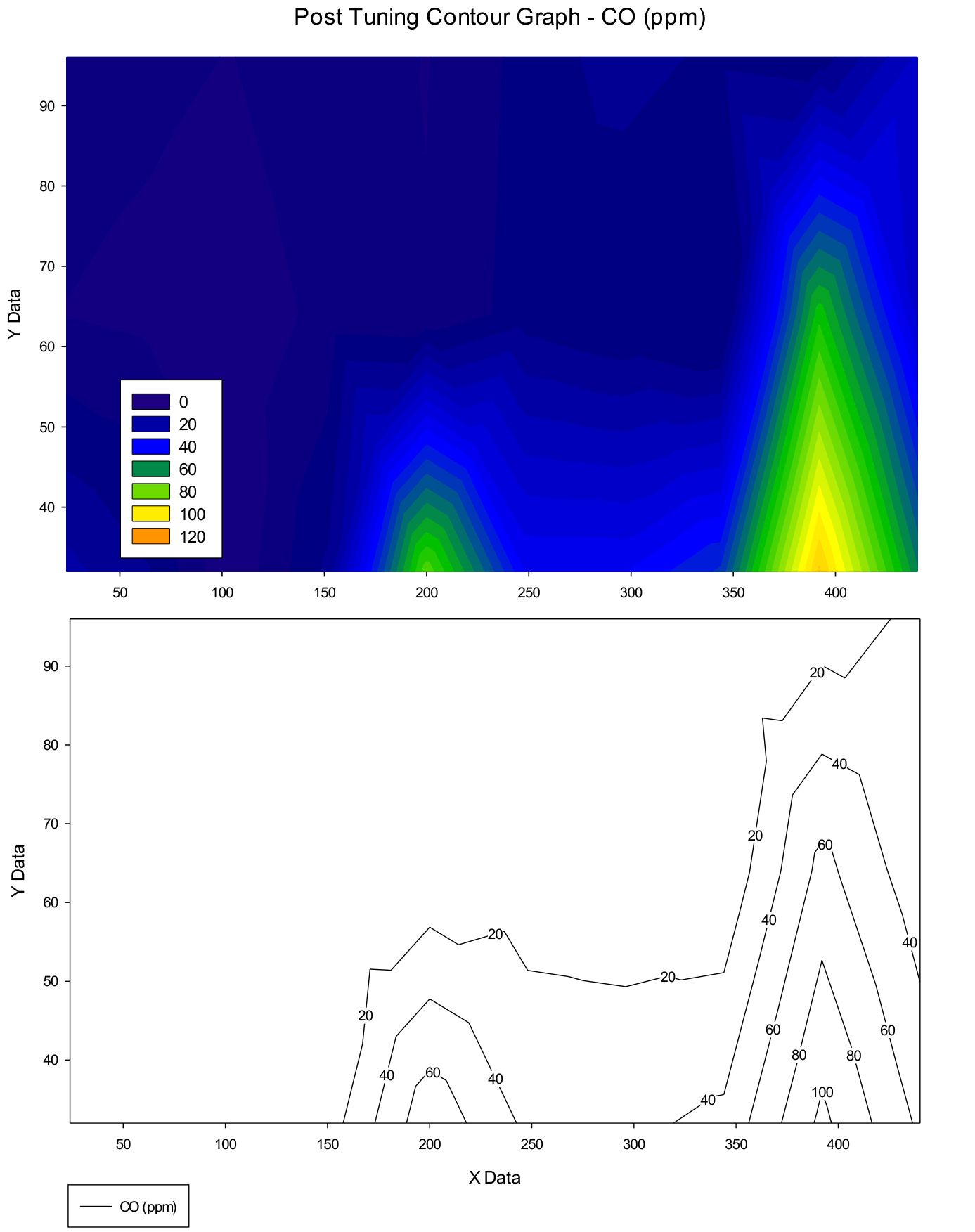

Case History: Pre- and Post-Testing Performance Results

A recent MATS and HAPs compliance project performed by the SAS Global Combustion Tuning Group demonstrates the measurable benefits of precision tuning and emissions optimization.

Project Overview

The plant, an older coal-fired EGU exceeding 500 MW, was experiencing elevated NOx and CO emissions, unbalanced air flows, and poor fuel distribution. The SAS team conducted a comprehensive Pre-Test Assessment, followed by targeted tuning, calibration, and combustion component adjustments.

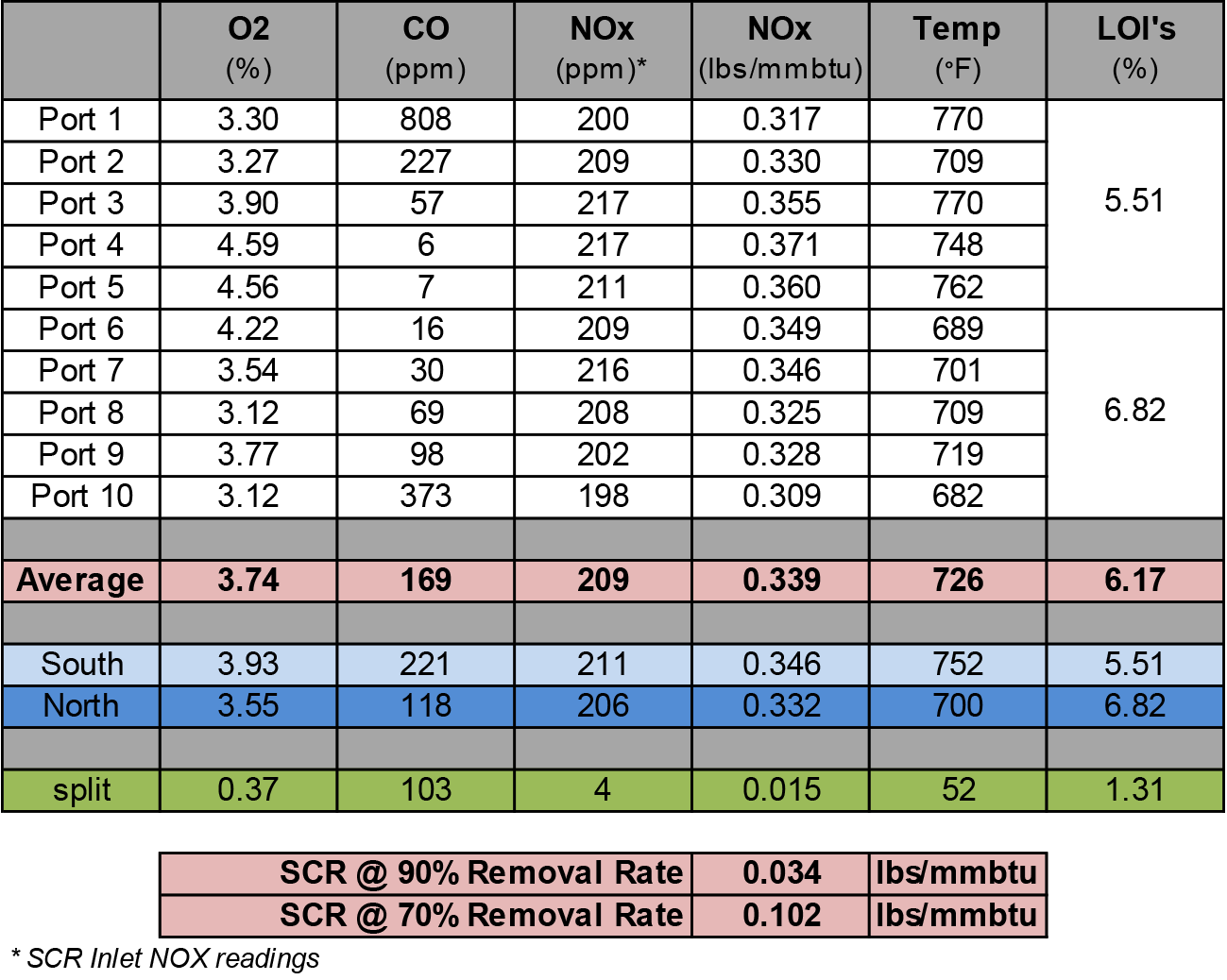

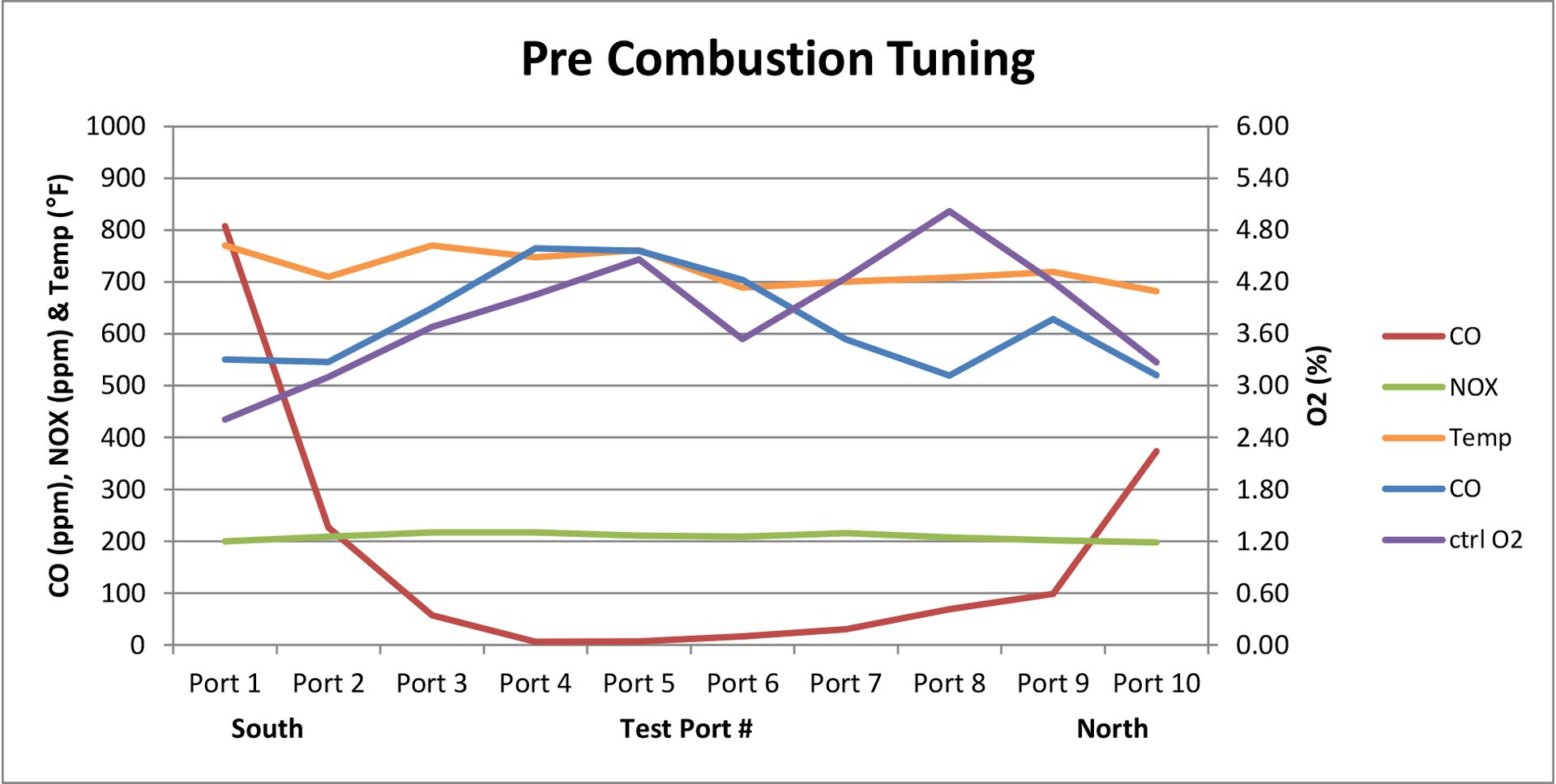

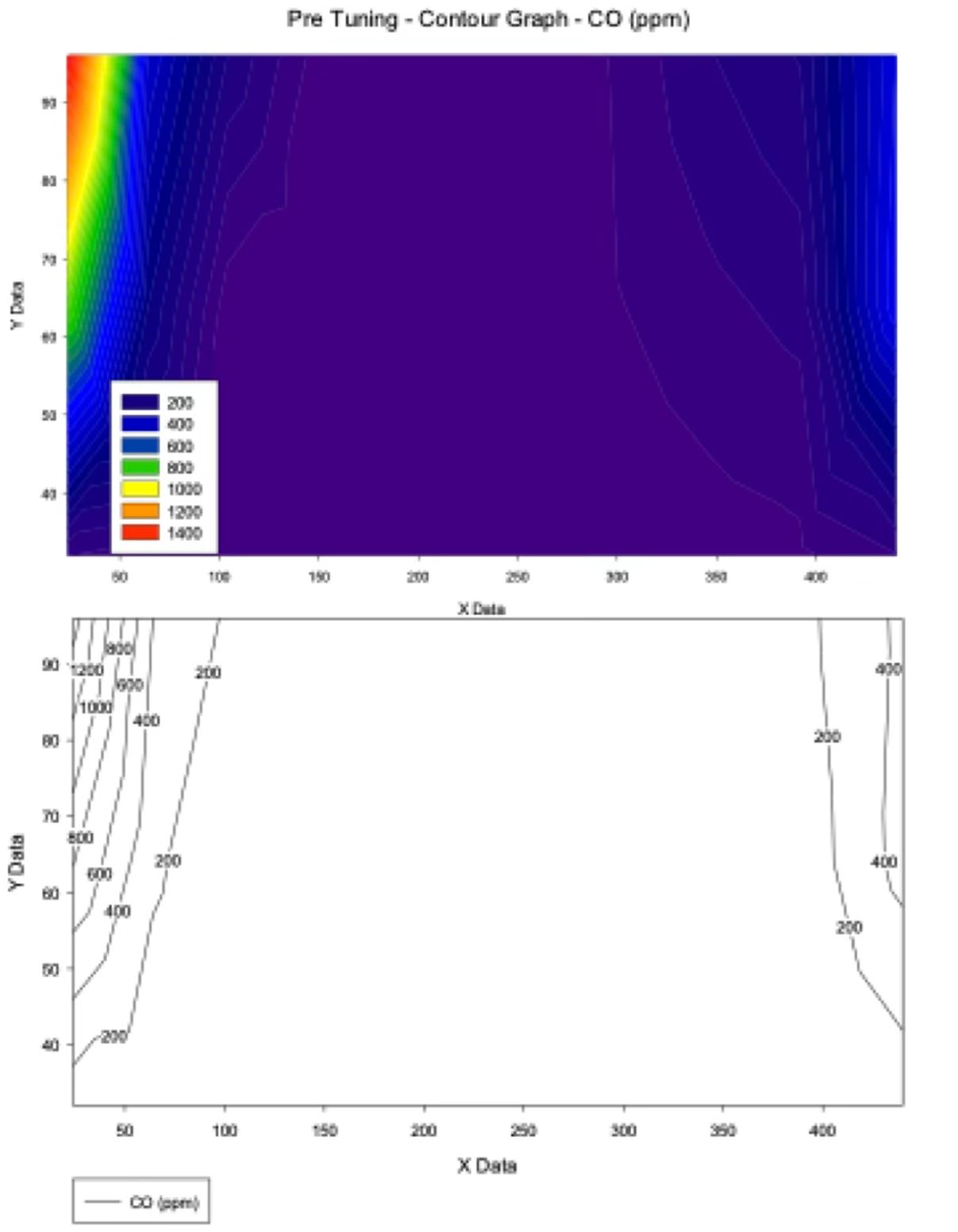

Pre-Test Summary

Before optimization, testing identified:

- High carbon monoxide peaks and inconsistent O₂ levels across the furnace

- Unstable flame patterns with intermittent flame impingement

- Poor coal fineness and uneven fuel distribution

- Reduced efficiency and visible opacity spikes during load swings

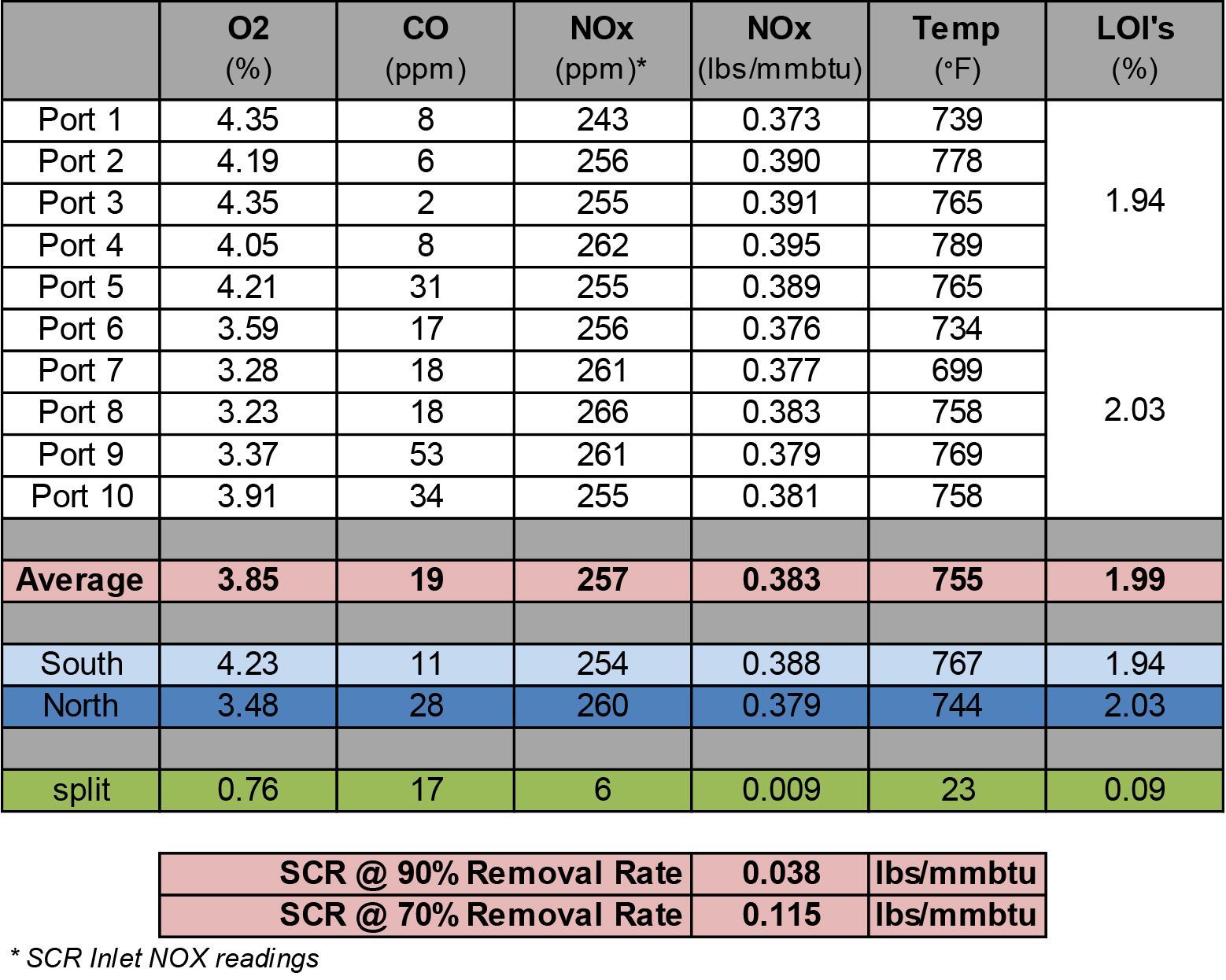

Post-Tuning Results

Following SAS’s adjustments and component enhancements, the improvements were immediate and quantifiable:

- CO emissions decreased by over 40%

- O₂ levels stabilized across all test locations, improving combustion uniformity

- NOx reductions averaged 10–15%

- Heat rate improved by approximately 1.5%

- Fuel balance variation reduced by nearly 50%, enhancing mill performance

- Opacity events were eliminated, and overall combustion stability significantly improved

Graphical data from the case study clearly illustrates lower emissions and tighter control bands post-tuning, confirming measurable gains in both environmental and operational performance.

Partnering for Performance and Compliance

MATS and HAPs compliance is more than just meeting EPA limits, it’s an opportunity to modernize your plant’s combustion performance, reduce emissions, and restore lost megawatt capacity.

SAS Global Corporation provides the testing, technology, and tuning expertise to help you achieve both regulatory certainty and operational excellence. Whether you need a full compliance audit, combustion optimization, or replacement components, SAS is your partner in cleaner, more efficient power generation.

Ready to Schedule a MATS/HAPs Compliance Assessment?

Contact SAS Global Corporation’s Combustion Tuning Group today to discuss how we can help your facility stay compliant, efficient, and competitive in a changing power generation landscape.