Harnessing Wear-Resistant Liners & Components in Pulp & Paper: Boosting Uptime, Safety & ROI

Wear-Resistant Liners & Components in Pulp & Paper:

Boosting Uptime, Safety & ROI

Wear is a constant adversary within the Pulp and Paper Industry. Between abrasive slurries, corrosive chemicals, heavy impact from logs and chips, and continuous material flow, virtually every piece of equipment suffers from some type of wear. It is seen from the woodyards to chemical recovery systems. Over the years, we’ve seen again and again how selecting the right wear-resistant materials and components can transform maintenance schedules, raise safety standards, and deliver measurable gains in productivity and cost efficiency.

Why Proper Wear-Resistant Materials Are Critical

- Reducing Maintenance Costs

When components are built or lined with materials that resist abrasion, impact, erosion and corrosion far better than standard steel, they simply last longer. That means fewer replacements, fewer emergency repairs, less labor, and more predictable budgeting. - Minimizing Downtime

Unscheduled outages are among the costliest events in pulp and paper mills. Every hour a chipper is down, or a conveyor in the woodyard is off, is lost production, and often cascading delays elsewhere. Properly selected wear materials allow equipment to stay online longer, smoothing the production flow. - Improving Safety

Maintenance often involves exposure to hazards—mechanical, chemical, and ergonomical. Less frequent maintenance = fewer opportunities for accidents. When components fail suddenly, it can create safety risks (e.g. flying debris, structural failure, exposure to chemicals). Robust wear liners help avoid catastrophic failures. - Enhancing Reliability and Efficiency

Components that maintain their shape, integrity, and smoothness (chutes, hoppers, pipe systems etc.) help ensure material flow is consistent, reducing clogging, energy waste (motors working harder), and quality defects. Smooth wear-resistant surfaces also help reduce friction, carryback, and hang-ups. - Handling Harsh Environments

Woodyard activities, chip handling, chemical recovery, bleaching, etc., expose components to abrasion, impact, corrosion, high wear zones. Standard materials often degrade quickly. Specialized alloys, overlay plates, carbide coatings, etc., are engineered for exactly those conditions.

Where the Gains Are Realized: Key Areas in a Pulp & Paper Facility

Below are some typical zones or equipment within the Pulp and Paper Industry where wear resistance has major impact, along with examples in service life improvements.

| Zone / Component | Common Wear Issues | Benefits of Upgraded Wear-Resistant Material | Service Life Increase & ROI Examples |

|---|---|---|---|

| Wood Yard / Log Handling (log feed chutes, log line conveyors, debarking teeth, chipper hoods) | High impact from logs, abrasion from bark, chips, foreign objects; seasonal & weather effects (snow/ice carryover) | Chute liners, overlay hoods, hardfaced teeth reduce abrasion and impact damage; less frequent replacements and less unplanned shutdowns | For example, as noted in some industry sources, chain sprockets or log conveyors rebuilt or coated with wear-resistant materials have had wear life increase of 100-200%. |

| Conveyors, Chutes, Hoppers, & Transfer Points | Abrasion, hanging up of material, uneven wear due to flow patterns, vibration induced fatigue | Smooth overlay plates (low friction finishes), heavy-duty weld/overlay/cladded surfaces, properly designed liners to avoid turbulence or dead zones | At SAS Global, our chute liner systems built with proprietary overlay plates (SA6000®, SA2000®, SA1750CR®) have delivered lifetimes many times over what “stock” steel delivered. Example: RapidFlow® high-polish overlay reduces carry-back dramatically. |

| Chemical & Pulp Process Areas (hydrapulpers, cyclones, grit troughs, pumps, lime systems) | Erosion, corrosion, combined chemical + mechanical wear; aggressive slurries; high temperatures | Corrosion-resistant alloys, carbide overlay plates, ceramic inserts/coatings; proper design to reduce turbulence, appropriate material selection based on pH, abrasion, impact | Corrosion resistant wear plate such as SureAlloy with Stainless Steel Baseplate used in ejection strips or cyclone liners has boosted service life by up to 200%. |

| Forming, Screening, & Finishing Equipment | Abrasion of screen plates, wear of blades, fiber erosion, carryback affecting quality and downstream cleaning | Hardfaced screens, tough wear resistant alloys in refining elements, smooth surface carbide overlay to prevent buildup | Gains here are often not just in component life, but in reduced downtime for cleaning and less paper defect rate, so effective gains multiply. Some mills have cut maintenance outages from 10 weeks to 2 weeks by better component selection and planning. |

Real ROI: Putting Hard Numbers to Wear Material Investment

To justify investment, we need to benchmark the cost of premium wear materials vs. the cost of downtime, replacement, labor, safety risk etc.:

- Extended Lifecycle: In many woodyard applications, replacing standard steel parts with overlay/carbon/tungsten carbide materials has doubled or tripled component life. E.g. sprocket teeth, conveyor chains – life increased by 100–200% or more.

- Reduced Maintenance Intervals: Less frequent inspections, less “emergency” fixes, fewer partial shutdowns. If you typically replace a liner every 6 months, moving to a material which lasts 18 months means a 66% reduction in replacement cycles, labor, and associated downtime.

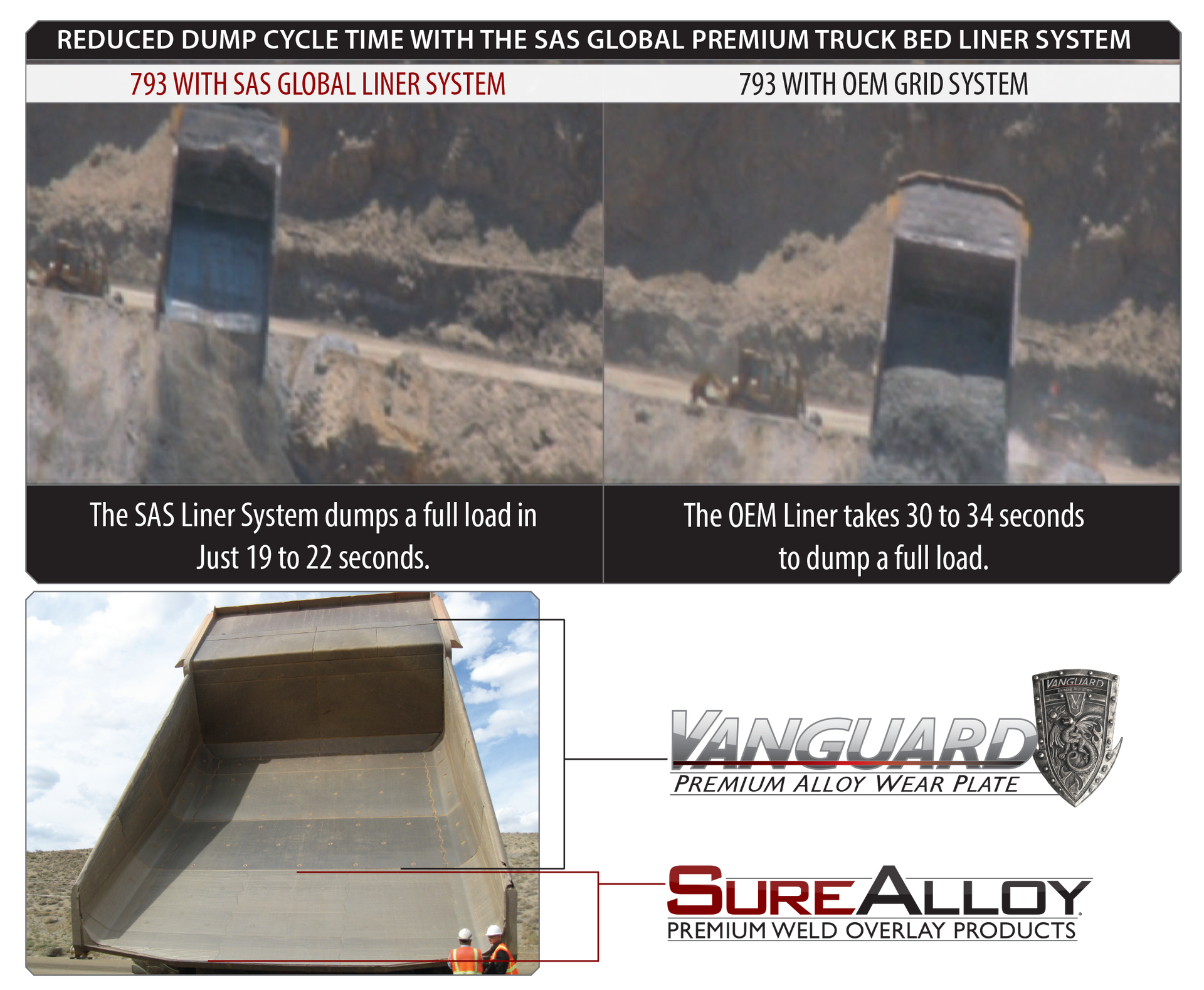

- Lower Total Cost of Ownership: Though premium carbide overlay materials (such as SureAlloy®) cost more per square foot, over their lifespan the cost per hour or per ton of throughput becomes far lower. Additionally, smoother surfaces or special overlays (such as RapidFlow®) can reduce friction and carry-back, lowering energy use and cleaning costs.

- Safety and Regulatory Savings: Fewer breakdowns means fewer injury risks; less exposure to maintenance in hazardous locations; possibly fewer regulatory incidents or downtime associated with safety investigations.

- Operational Efficiency Gains: More consistent throughput; fewer variations in process caused by failing parts; better quality control leading to fewer rejects and less waste.

As an example: one plant might see an unscheduled outage every 2–3 months due to liner or chute failure, taking 8-12 hours for each repair. If upgrading materials reduces that to once per year, that’s dozens of hours saved, plus not losing production or having to “clean up” after failure. Multiply that by labour cost, lost production margin, and other costs and savings can often pay back a premium wear solution in 1–2 years, or less.

SAS Global: Engineered Solutions Approach

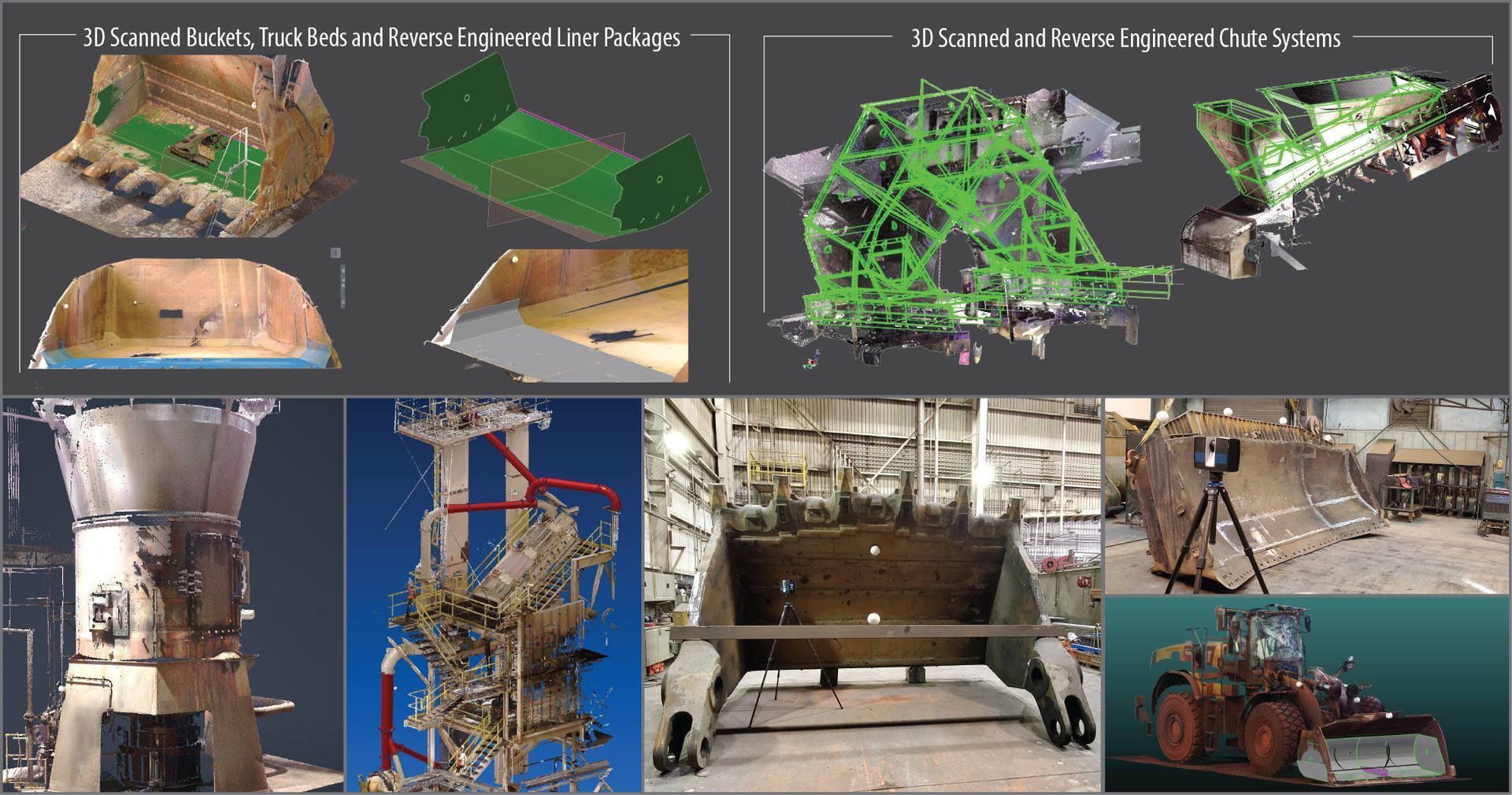

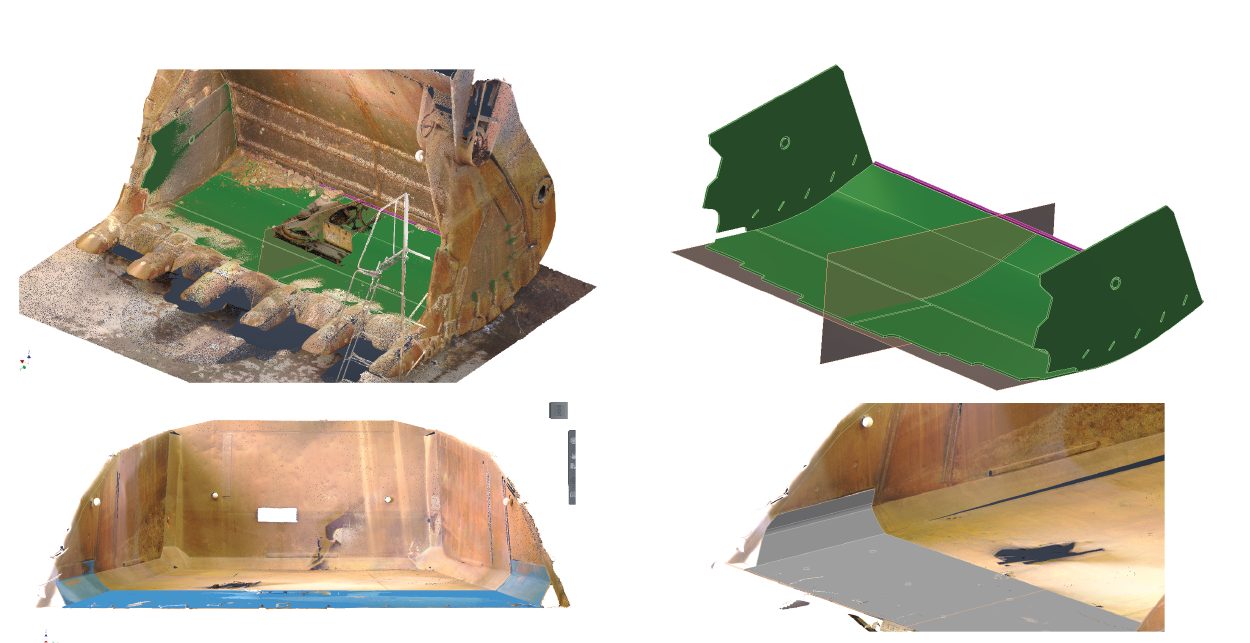

At SAS Global, we don’t just sell wear plates. We provide a fully customized engineered wear protection solution:

- SAS has over 70 years of experience with wear-resistant materials to rely on when choosing materials with the right hardness, toughness, corrosion resistance, and impact resistance for each application. (E.g. overlay vs through-hardened alloy.)

- SAS offers proprietary materials like SureAlloy® (SA6000®, SA2000®, SA1750CR®, RapidFlow®), Vanguard®, etc., each optimized for specific wear mechanisms.

- SAS custom engineers components (chutes, liners, hoppers, screws, cyclones etc.) to reduce turbulence, hang-ups, abrasion hotspots. Proper fit matters, misaligned or poorly installed liners can fail prematurely.

- Custom fabrication & ease of installation matter: fewer hours to install, fewer adjustments needed, less impact on production schedule.

Safety & Environmental Considerations

Often overlooked in purely cost-based ROI is how improved wear-resistant materials enhance safety and environmental performance:

- Fewer maintenance interventions in hazardous zones: Less exposure of personnel to moving machinery, hot surfaces, or corrosive/abrasive materials.

- Less dust, fewer airborne particles: When material flows smoothly (rather than in a turbulent fashion causing dust), air quality improves.

- Reduced leaks or spillage: Worn liners in pumps, pipes, troughs can lead to leaks of slurry or chemicals—leading to slip risks, environmental contamination, regulatory risk.

- Energy savings: Worn equipment often operates inefficiently—pumps and conveyors draw more power; friction losses and turbulence waste energy. Smoother and proper wear protection helps reduce those losses.

Challenges & Best Practices

To maximize value, you shouldn’t just buy the hardest wear-resistant material. Common poor material selection pitfalls include:

- Mismatch between wear mechanism and material: Abrasion, impact, and corrosion each require different material properties. Very hard but brittle materials may crack under impact; tough materials may wear quickly under abrasion if the hardness is low.

- Poor fabrication / improper fit: Gaps, misalignment, and undersized fasteners all can degrade performance and accelerate wear.

- Neglecting design of contact zones and flow dynamics: Chute angles, material velocity, flow turbulence, and impingement angle—all affect wear significantly. Good material won’t fix a bad design.

- Ignoring cost of downtime: It’s easy to focus purely on material cost; but labor, lost production, safety risk, and variable quality often dwarf the cost of premium wear materials.

- Lack of monitoring: To know whether an upgrade is performing, you must track wear rates, inspect components, record downtime, and compare. This data is essential.

Conclusion: Wear Liners Are Not a Luxury, They’re a Strategic Asset

In today’s Pulp & Paper Industry environment, margins are tight, regulatory and safety pressures are high, and outage costs are steep. Premium wear-resistant liners and components are not just “nice to have”—they are strategic assets. The proper material selection, coupled with skilled engineering, installation, and monitoring, delivers:

- Longer service life

- Less unexpected downtime

- Reduced maintenance and safety risk

- Better product quality and consistency

- Lower total cost of ownership

At SAS Global, we view every wear issue, not just the symptom, but the upstream design, material choice, and downstream maintenance plan. Pulp and Paper Industry Facilities that take a systems approach; matching the right wear materials to the specific wear environment in the woodyard, fiber handling, chemical zones, etc., are those that achieve the greatest returns.

If your facility is dealing with frequent component failures, safety incidents during maintenance, or spiraling maintenance costs, it may well be that the wear materials just aren’t right for the job. Investing in engineered wear solutions is one of the most direct levers you have to improve production performance, safety, and profitability.