Maximize Uptime, Minimize Maintenance How Long-Service-Life Components Transform Metal Recycling Operations

Maximize Uptime, Minimize Maintenance

How Long-Service-Life Components

Transform Metal Recycling Operations

Every metal recycling plant knows this reality: your equipment is under constant attack.

From inbound scrap to airborne fines, every second of operation grinds away at your shredders, shears, fans, and chutes. The harsh mix of impact, abrasion, heat, and vibration is relentless, and downtime is expensive.

At SAS Global Corporation, we’ve spent decades engineering ways to fight that battle. Our long-service-life wear components, liners, and fabrication techniques are designed to survive and outperform under the punishing demands of the metal recycling industry.

It is not just about about longer wear life, it’s about

predictable performance, measurable ROI, and fewer production interruptions.

The Harsh Reality of Wear in Metal Recycling

Recycling operations are unique. Unlike cement or aggregate plants, you’re not handling uniform material. You’re processing unpredictable, high-impact, sharp-edged, dense scrap from car bodies and rebar to cast iron and aluminum.

That creates three distinct wear modes:

- High-Impact Loading:

Auto-shredders, shear blades, and bailer rams experience massive impact forces that quickly fatigue conventional steels. - Severe Abrasion:

Chutes, hoppers, conveyors, and fan housings suffer continuous erosion from metallic fines, wires, and dust. - High-Temperature Friction:

Heat buildup during shredding or pneumatic conveying accelerates wear and oxidization, shortening the life of mild and AR steel components.

These forces combine to form a perfect storm of material loss, component distortion, and unplanned downtime. The result:

lost tons, lost production hours, and inflated maintenance budgets.

What Downtime Really Costs

A single unplanned shutdown can ripple through the entire operation:

- Production loss: If your shredder averages 200 tons/hour, even four hours of downtime equals 800 tons unprocessed, potentially $16,000 to $20,000 in lost profit.

- Maintenance labor: Replacing worn liners may require cranes, confined-space permits, welders, and downtime coordination across shifts.

- Replacement parts and consumables: If your liners wear through quickly, you’re not just replacing the liners, you’re consuming labor, hardware, and lost efficiency every few weeks.

Multiply that by every chute, elbow, and liner across the plant, and the annual impact can easily exceed hundreds of thousands of dollars.

The SAS Global Advantage: Engineering for Extreme Duty

SAS Global products are designed to:

reduce wear at the source and extend service life beyond conventional expectations.

We combine

premium materials,

precise fabrication, and

decades of application expertise across every wear zone in your plant.

SureAlloy® Premium Carbide Overlay Plate

Our proprietary SureAlloy® family (SA1750CR, SA2000, SA6000) features metallurgically bonded chromium carbide overlays fused to a mild steel base plate.

- Up to 6× longer life than AR400–AR500 steels.

- Exceptional resistance to fine-particle abrasion and sliding wear.

- Available in standard and RapidFlow® smooth-surface variants for improved material movement.

- Custom fabricated into chutes, liners, fan housings, piping, elbows, and transitions.

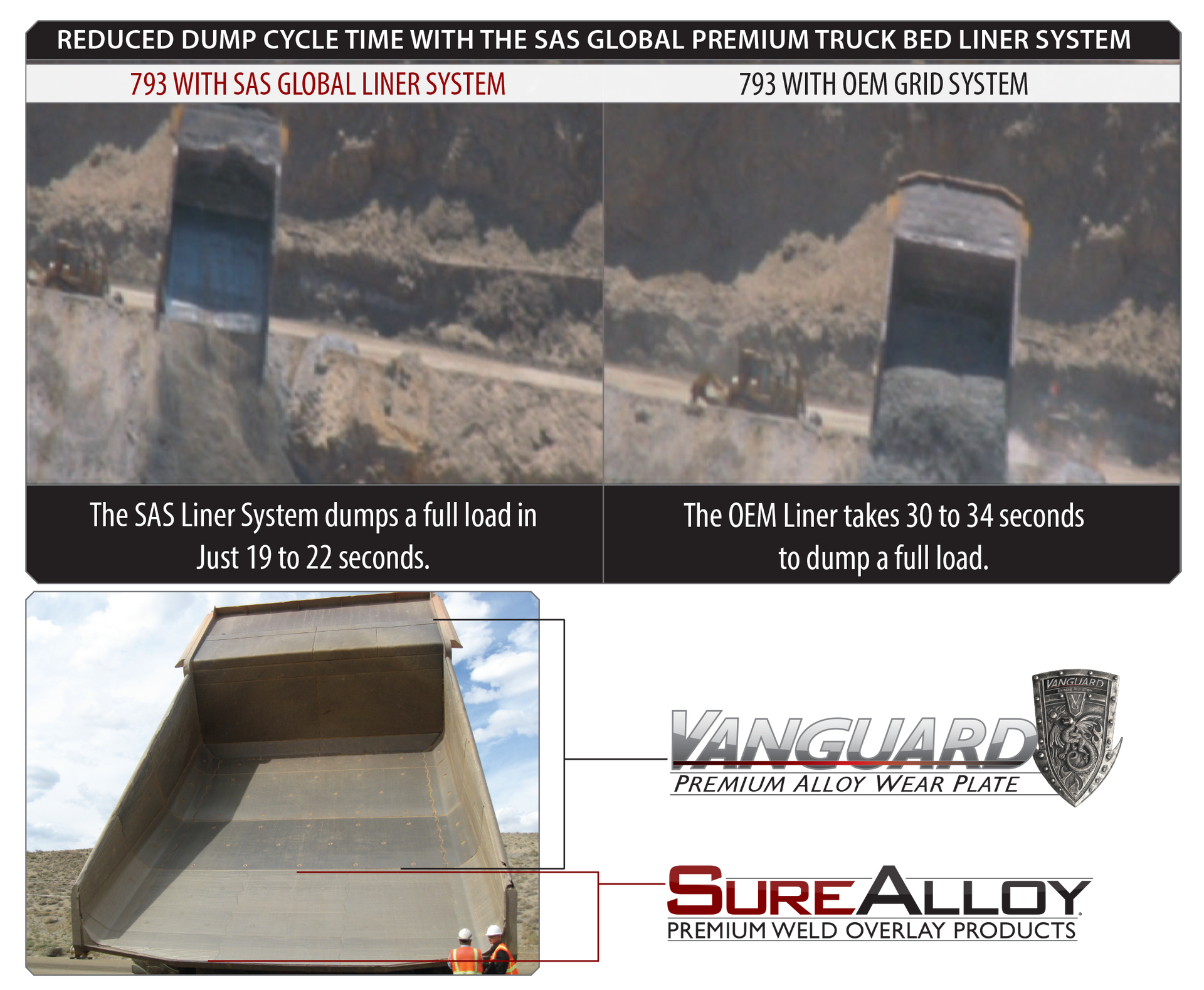

Vanguard® Premium Alloy Wear Plate (500 Brinell)

Through-hardened, high-impact alloy plate designed for dynamic and structural areas:

- Ideal for rotor housings, shredder frames, and bailer compression zones.

- Combines toughness and hardness — critical for heavy scrap impact.

- Maintains dimensional stability and weld integrity under cyclic load.

CladPipe

Cladtec, division of SAS Global, proudly manufactures CLADPIPE in the USA. CLADPIPE is a hardfaced wear resistant pipe with the inner diameter cladded with one of Cladtec’s premium hardfacing materials.

- Ranging from a 5.5” finished inner diameter (with cladding applied) to a maximum 26” inside diameter pipe. (special runs up to 30” ID may be possible based on wall thicknesses)

- Cladding thickness: 1/8” through 1/2“ depending on hardfacing material utilized.

| Equipment Area | Common Wear Points | SAS Wear Solution | Key Benefits |

|---|---|---|---|

| Auto & Mega Shredders | Feed chutes, housing liners, grates, hammers | SureAlloy® & Vanguard® housings and liners | Longer liner life, fewer rebuilds |

| Pre-Shredders & Bailers | Compression faces, drop zones, sidewalls | Vanguard® & SureAlloy® wear liner systems | Reduced deformation, consistent feed pressure. Longer Wear Life |

| Shears | Blade carriers, discharge troughs | Vanguard® & SureAlloy® bolt-on or weld on liners | Maintains shear precision & cycle time |

| Chutes & Hoppers | Impact & sliding zones | Custom-fit SureAlloy® liners and Complete fabricated chutes & hoppers | Smooth flow, reduced hang-ups |

| Fans & Cyclones | Housings, impellers, intake elbows | SureAlloy® RapidFlow® overlay | Longer wear intervals, consistent airflow |

| Dust Collection & Conveyance | Pipe elbows, transitions | CladPipe & SureAlloy® Fabricated Pipe | Longer wear intervals, consistent airflow |

Each component is engineered, fabricated, and quality-inspected at our Michigan and Texas manufacturing facilities, ensuring ISO 9001:2015 compliance, precision fit, and rapid delivery.

ROI: Proving the Business Case for Long-Life Wear Components

Maintenance and Operations Managers often face the same question:

“Can we justify the higher up-front cost of premium liners?”

The answer is almost always yes — and provable.

1. Cost Per Ton Reduction

When a $50,000 set of liners lasts four times longer than a $35,000 set of AR steel, your annualized cost drops by 60–70%.

| Standard AR Liners | SAS SureAlloy® | |

|---|---|---|

| Liner cost | $35,000 | $50,000 |

| Avg. life | 3 months | 12 months |

| Replacements/year | 4 | 1 |

| Annual liner cost | $140,000 | $50,000 |

| Annual savings | $90,000 |

That excludes labor, crane rental, and lost production time — which can double the savings.

2. Maintenance Labor Savings

Each liner change may consume 40–60 man-hours. Extending change intervals by 3× frees hundreds of labor hours annually.

3. Uptime & Reliability

Eliminating just one unplanned outage can save over $100,000 in lost production for a high-throughput facility.

4. Extended Equipment Life

When liners protect housings and weldments from direct contact wear, major rebuild cycles stretch from every 3–5 years to 8–10 years, reducing long-term capital cost.

Maintenance Strategy: Turning Wear Management into Predictable Performance

Treat wear protection as a

program, not a product. SAS Global supports you with the tools to build a proactive, data-driven maintenance strategy:

1. Wear Audits & Condition Monitoring

We inspect and document liner condition, wear patterns, and failure points.

This helps identify whether abrasion, impact, or flow turbulence is driving wear — allowing better material selection and design optimization.

2. Predictive Maintenance Scheduling

Using liner thickness and tonnage data, we help facilities forecast change-out intervals and align with scheduled outages, preventing catastrophic wear-throughs.

3. Continuous Improvement Feedback Loop

SAS engineers track performance data across multiple customers and use it to refine plate chemistries, overlay thicknesses, and joint designs.

4. Standardization & Inventory Simplification

By adopting a plant-wide wear-material standard (e.g., SureAlloy® SA2000 for fine abrasion, Vanguard® 500 for impact), facilities can reduce SKUs, simplify welding procedures, and streamline purchasing.

Why Maintenance and Operations Managers Choose SAS Global

- Full-System Engineering: We don’t just sell plate — we engineer, design, and fabricate complete wear systems.

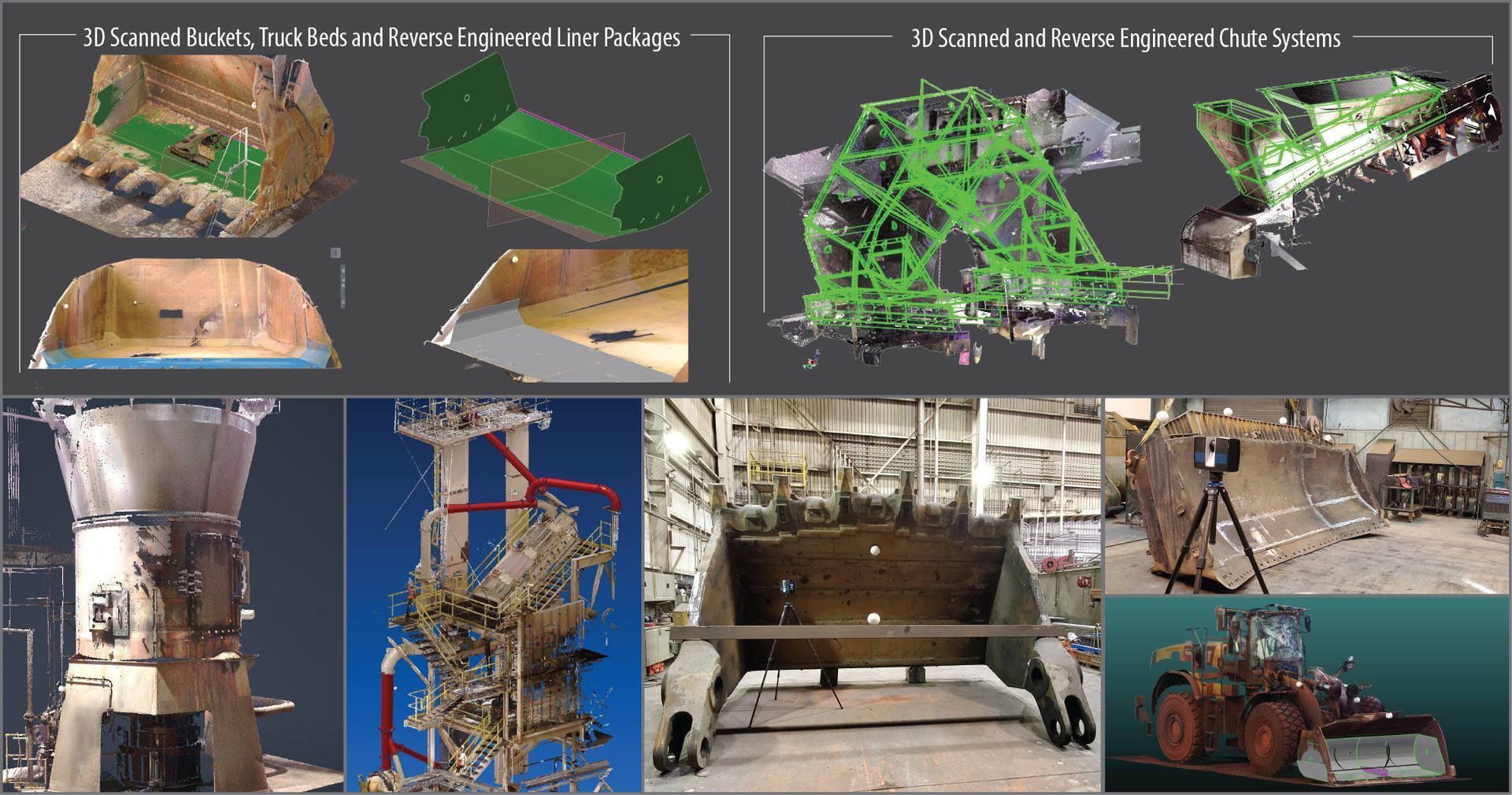

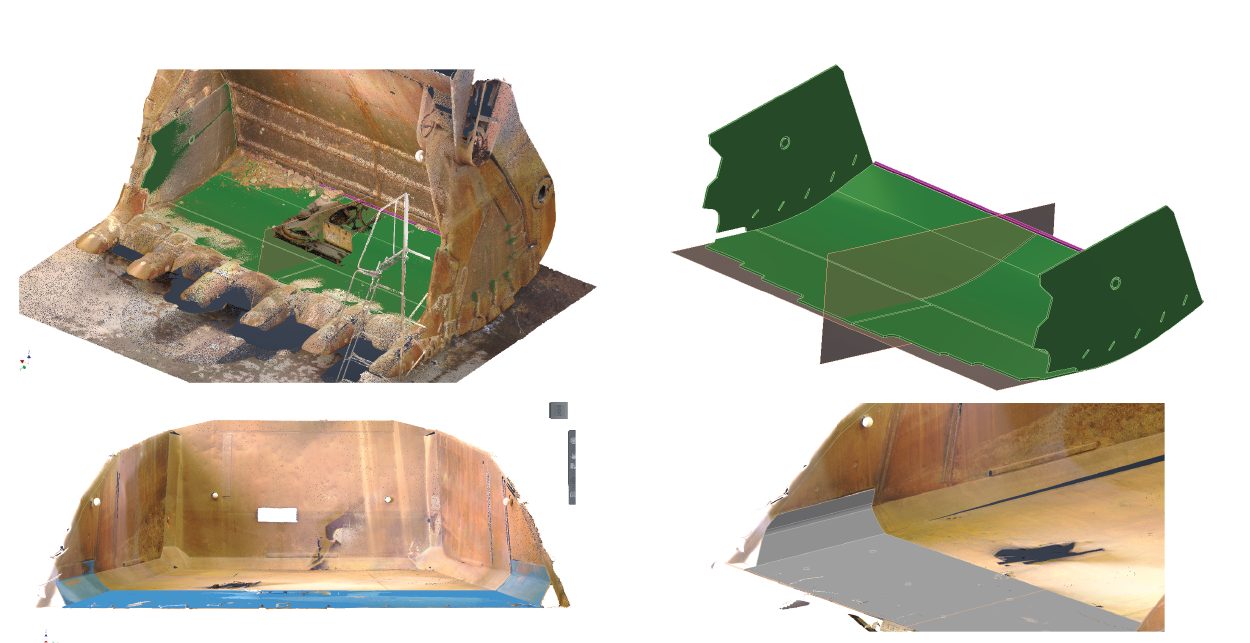

- Custom Fit and Installation Support: Precise 3D CAD modeling and 3D Laser Scanning field measurement ensure perfect liner fit.

- Certified Quality: ISO 9001:2015 certified fabrication with documented weld procedures and inspections.

- Proven ROI: Documented performance improvements across recycling, steel, and power industries.

- Fast Response: In-stock materials and nationwide field support minimize downtime.

Ready to Turn Maintenance Savings into Profit?

If you’re a Maintenance or Operations Manager responsible for uptime, production, and cost control in a metal recycling facility, SAS Global is your partner for measurable improvement.

We’ll help you:

- Audit your current wear zones

- Identify the best materials and liner configurations

- Model expected ROI and payback periods

- Deliver fabricated liners ready to install on your next shutdown

Contact SAS Global today to schedule a

Wear Audit or ROI Consultation.

Visit

sasglobalcorp.com/metal-recycling-industry for more details.

Let’s build your recycling plant to last, one long-life component at a time.