The Importance of Fuel Pipe Balance and Air-to-Fuel Balance in Coal-Fired Power Plants

The Importance of Fuel Pipe Balance and Air-to-Fuel Balance

in Coal-Fired Power Plants

Fuel pipe balance and air-to-fuel balance are critical to achieving efficient combustion, lower emissions, and reliable furnace performance in coal-fired power plants. Imbalances at the pulverizer outlet cause wide variations in burner performance, leading to poor efficiency, higher emissions, slagging, and reliability issues.

Despite attempts to address these challenges with airflow controls, adjustable orifices, and burner modifications, true balance can only be achieved at the source where pulverized coal leaves the mill. That is where the SAS Global Corporation Patented Mill Modernization Products deliver proven results.

The Problem: Fuel Distribution Imbalance

Even with balanced primary airflow, it is common for coal pipe fuel flow to vary by ±30% or more. This creates several serious issues:

- Fuel-rich burners (high coal, low air) operate below the desired air/fuel ratio, leading to increased unburned carbon (UBC), loss on ignition (LOI), slagging, and poor heat rate.

- Air-rich burners (high air, low coal) act as thermal NOx generators, driving up emissions. The lean fuel conditions also cause heavy amounts of thermal shock to the burner nozzles/tips.

- Imbalanced heat input across the furnace causes steam temperature control issues and reduced boiler efficiency.

- Elevated UBC and LOI

negatively impact flyash quality and ASTM classification for use in concrete.

In short, poor balance decreases efficiency, raises fuel costs, increases emissions, and reduces equipment life.

Common Industry Solutions and Their Limitations

Many plants have attempted to mitigate fuel imbalance through:

- Secondary and overfire air control: improves combustion margin but cannot fix poor distribution at the mill outlet.

- Adjustable or fixed orifices alone: effective only when air/fuel ratios between pipes are already close. Orificing adjusts velocity but does not correct the air-to-fuel ratio imbalance.

The SAS Solution: Correcting the Problem at the Source

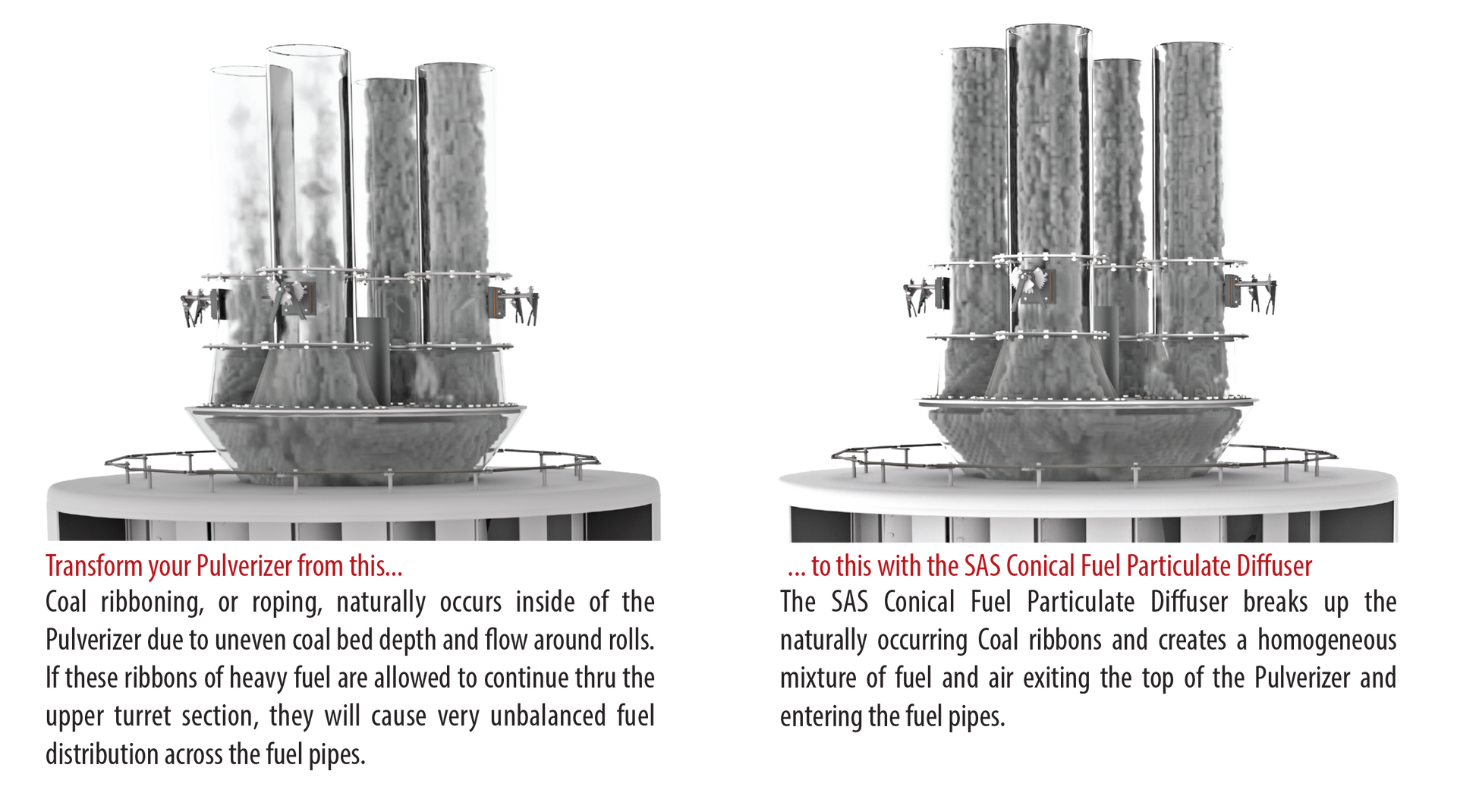

SAS Conical Fuel Particulate Diffuser

(Patent Pending)

Balance Fuel Flows | Improve Air-Fuel Ratios | Reduce Emissions

The

SAS Conical Fuel Particulate Diffuser was designed through advanced modeling, extensive field testing, and plant installations to address the imbalance where it begins at the mill outlet.

How It Works:

- Breaks up natural “coal ribbons” that form inside the mill.

- Homogenizes pulverized coal and air before entering fuel pipes.

- Distributes fuel evenly across all pipes, ensuring consistent air-to-fuel ratios.

- Enables proper use of orificing to fine-tune fuel pipe balance.

Key Benefits:

- Improved combustion efficiency.

- Reduced NOx, CO, LOI, and UBC.

- More stable flame and heat input balance.

- Compatible with MPS, CE, MBF, IHI, Riley, and FW pressurized mill designs

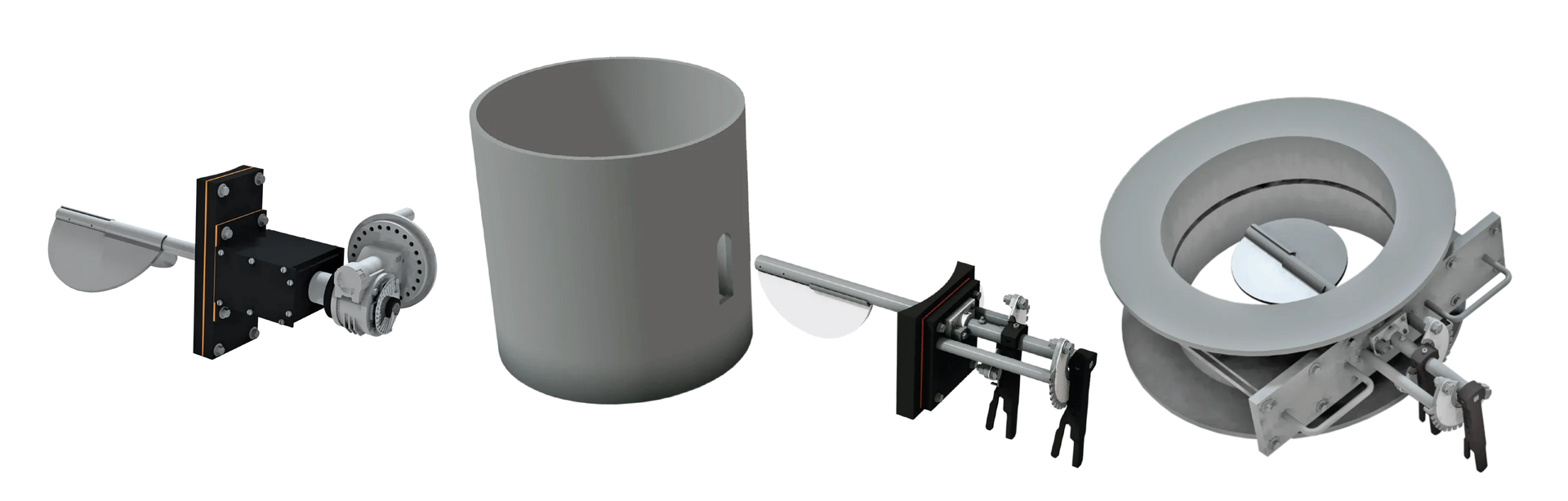

SAS CV-Style Adjustable Orifice (Patented)

Precision Control | Reliable Adjustment | Long-Term Performance

The

SAS CV-Style Adjustable Orifice complements the SAS Conical Fuel Particulate Diffuser by fine tuning of fuel pipe balance while online, after the air-to-fuel ratio distribution has been corrected.

Why It’s Different from Other Orifices:

- Unique Center V Shape: Delivers smooth, predictable flow restriction.

- Jam-Proof Design: Prevents coal impaction issues common in conventional orifices.

- Stays Fully Adjustable: Even after years of service.

- Simple Installation: Directly into existing fuel pipes or Orifice Box, or into new pipe spools.

- Options to Suit Needs: Available with manual gearbox or handle adjustment options.

Key Benefits:

- Fine-tuned system balancing.

- Long-term reliability and adjustability.

- Consistent combustion improvement with minimal downtime.

The Combined Advantage

By integrating both SAS Mill Modernization Diffusion Technology Products, power plants can finally achieve

true fuel pipe and air-to-fuel balance:

- The Conical Fuel Particulate Diffuser creates a homogenous mixture of proper air-to-fuel distribution at and exiting the mill outlet.

- The

CV-Style Adjustable Orifice allows precise fine tuning of the fuel pipe balance while online.

Together, they provide:

- Improved combustion efficiency and reduced heat rate.

- Lower NOx, CO, and UBC emissions.

- Better steam temperature control and furnace stability.

- Increased flyash quality and usability.

Fuel pipe imbalance has been a persistent challenge for coal-fired power plants, limiting efficiency and driving up emissions. The SAS Global

Conical Fuel Particulate Diffuser and the

CV-Style Adjustable Orifice offer a proven, cost-effective solution by addressing the problem at its source.

With these technologies, coal-fired power generation plants can unlock higher efficiency, lower emissions, and improved operational reliability. Ensuring compliance and profitability in today’s demanding energy market.

Modernize your Coal Mill / Pulverizer. Balance your system. Improve your bottom line with SAS Global Diffusion / Fuel Pipe Balancing Technology.