Modernize for Maximum ROI: How the SAS Global Turnkey Coal Mill Modernization Program Transforms Efficiency, Reliability, and Profitability

Modernize for Maximum ROI:

How the SAS Global Turnkey Coal Mill Modernization Program Transforms Efficiency, Reliability, and Profitability

In today’s competitive power generation market, success is measured by more than megawatts. It’s measured by efficiency, emissions, uptime, and cost control. As fuel and maintenance costs climb, one area has proven to be the hidden key to performance and profit: your coal pulverizer / mill.

A single underperforming mill can waste millions of dollars per year in excess fuel and unplanned maintenance. Poor fineness, unbalanced fuel flow, and air leakage reduce boiler efficiency, increase emissions, and accelerate wear.

That is why more utilities are turning to the

SAS Global Corporation Turnkey Coal Mill / Pulverizer Modernization Program. This is a comprehensive engineering, manufacturing, and installation solution that restores mill performance, improves plant heat rate, and delivers

rapid, measurable ROI.

A Proven Modernization Partner

With over 70 years of experience, SAS Global is a recognized leader in

wear-resistant materials and

high-performance modernization systems. The SAS turnkey program combines

engineering expertise, patented technologies,

field installation services, and real-time

diagnostic testing and combustion tuning. All from a single, U.S.A. based source.

SAS modernizes and optimizes all major mill designs, including:

- MPS and MBF Mills (Babcock Power / Foster Wheeler)

- IHI Mills (IHI / Hitachi)

- CE HP, RP, RS, RB

- EL Mills

- Riley Ball Mills

- FW Ball Mills

Each modernization project is custom-engineered to the plant’s operating conditions, fuel characteristics, and performance objectives, delivering quantifiable improvements in capacity, fineness, emissions, and maintenance cost.

A Turnkey Approach: From Diagnostics to Performance Verification

Unlike partial upgrades or component-only suppliers, SAS delivers a true turnkey modernization, managing every phase of the project from baseline analysis to combustion tuning and verification.

Phase 1: Diagnostic Testing and Performance Analysis

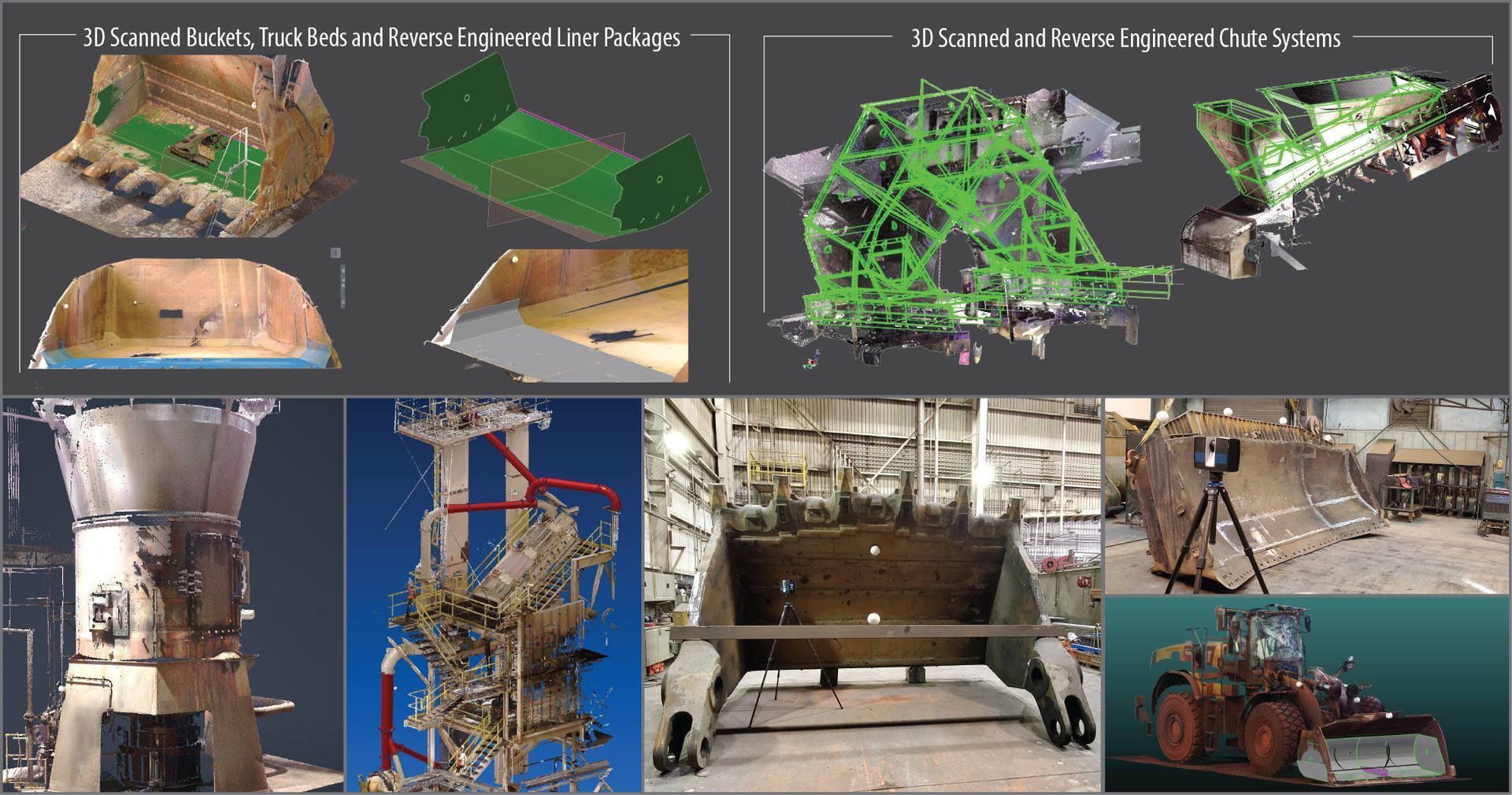

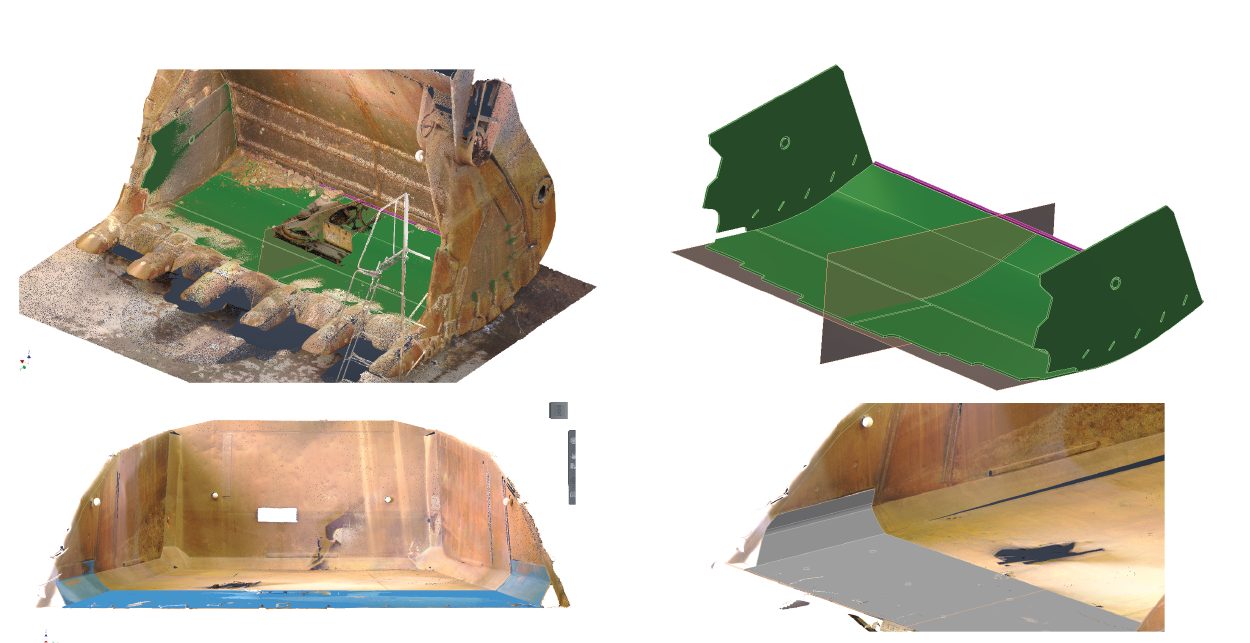

SAS begins with on-site mill performance testing using its mobile 35-foot combustion diagnostics laboratory. Equipped with advanced instruments for isokinetic fuel flow measurement, air/fuel pipe balance measurements, fineness testing, and HVT boiler mapping, SAS engineers collect the data needed to establish a clear performance baseline.

Testing includes:

- 100% isokinetic coal flow sampling

- Primary airflow measurements

- Coal fineness and fuel analysis

- Air/fuel ratio measurements

- HVT boiler testing

- Multi-stream flue gas and O₂/CO monitoring

- Fly ash LOI and burnout assessment

This data drives a detailed modernization report outlining the current performance gap, including areas where efficiency, balance, and wear life can be improved.

From there, SAS engineers design a

custom modernization plan that targets measurable outcomes with improved heat rate, lower emissions, and reduced maintenance costs.

Phase 2: Engineered Modernization Design

SAS applies decades of pulverizer engineering expertise to design solutions that fit into the existing mills while introducing modernized internals and materials.

Every component is designed and manufactured in the SAS Warren, Michigan facility, using precision fabrication methods, and premium wear resistant materials to ensure dimensional accuracy and a long wear life.

Key modernization components include:

- Patented Rotating Vane Wheel: Improves capacity and fineness, lowers motor amps, increases fuel drying, and reduces maintenance.

- Patented High Spin Static Classifier: Uses cyclone separation to dramatically improve classification efficiency and fineness control.

- Patent Pending Conical Fuel Particulate Diffuser: Breaks up fuel “roping” to balance air/fuel ratios across all coal pipes exiting the mill.

- Patented Adjustable CV-Style Orifice: Fine-tunes pipe-to-pipe balance while online.

- Patented Retractable Enhanced Flow Discharge (MPS/MBF/IHI): Boosts fineness and capacity while improving maintenance.

- Patented Pre-Riffle Diffuser: Balances fuel flowing through riffle systems.

- Patented Silver Bullet Exhauster Fan: Provides superior airflow and efficiency with extended wear life.

- Grinding Pressure Monitor System: Allows operators to visualize grinding performance in real time.

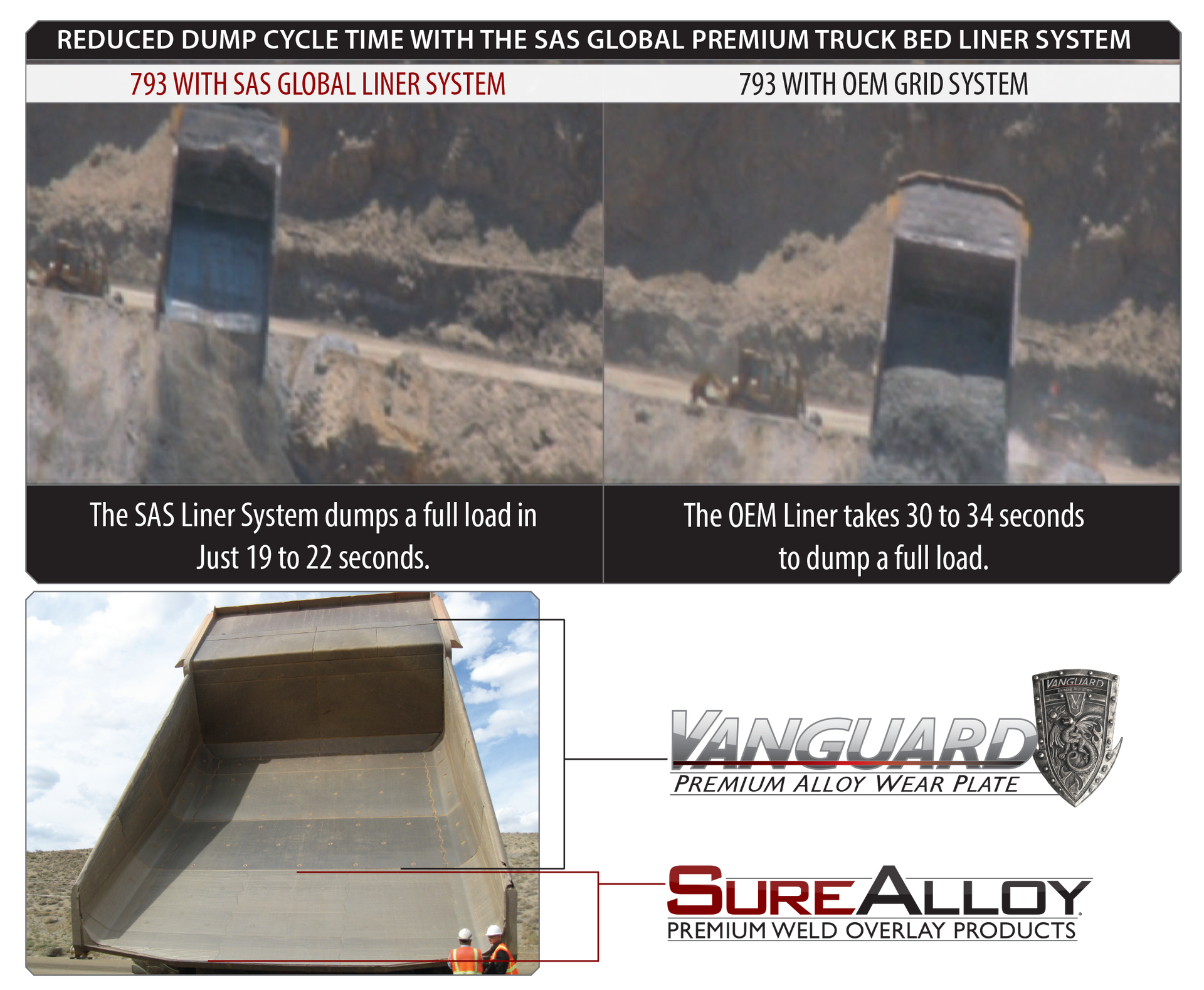

- SureAlloy® and Vanguard® Wear Liners: Protect high-wear surfaces with premium carbide overlay and/or premium alloy wear plate.

Together, these systems form the foundation of the SAS Mill Modernization Program. Providing a fully modernized pulverizer that delivers higher capacity, lower operating cost, and a fast return on investment.

Phase 3: Precision Manufacturing and Quality Control

SAS Modernization components are manufactured in the USA under ISO-certified quality standards. All fabrications are backed by in-house engineering, precision fabrication, and non-destructive inspection, ensuring that every modernization component is ready for years of reliable operation.

All modernization components are manufactured using premium

SureAlloy® and

Vanguard® wear-resistant materials. Including SA1750CR®, SA2000®, and SA6000® premium carbide overlay plates. These materials deliver longer wear life than OEM parts.

The SAS Cladtec Division applies proprietary CT-28 hardfacing materials to grinding rolls and tables, restoring worn parts to “better than new” condition.

Phase 4: Turnkey Installation and Field Services

Once manufactured, the SAS Field Services Division handles the complete installation process, from disassembly and component alignment to final commissioning.

Field supervisors bring decades of plant experience in pulverizers, fans, and material handling equipment. With in-house labor resources and full project management, SAS eliminates the need for third-party contractors, ensuring a single point of accountability and consistent quality throughout the project.

Field Service benefits include:

- Complete pulverizer rebuilds and overhauls

- Grinding roll/table hardfacing and alignment

- Experienced modernization component installation

- Safe, efficient installation under tight schedules

This integrated model shortens outage time, improves quality control, and reduces risk. All critical advantages in today’s fast-paced maintenance environments.

Phase 5: Performance Verification and Combustion Tuning

Following installation, SAS performs diagnostic testing using its mobile testing laboratory to verify performance gains and perform and fine tuning to optimize system performance.

Real-time measurements of velocities, fuel pipe balance, air-to-fuel ratio balance, O₂, CO, and NOx allow engineers to fine-tune air/fuel ratios, improve stoichiometry, and balance fuel flow across all mills.

Typical results include:

- 6–15% higher mill throughput

- 10–18% lower motor amps

- 8–12% finer grind distribution (up to 99.8% through 50 mesh)

- Reduced unburned carbon and slagging

- Reduction in emissions

- 5–10% improvement in boiler heat rate

The data is compiled into a comprehensive post-modernization report, giving plant managers a quantifiable ROI backed by actual field measurements.

Rapid ROI = Real-World Payback Results

When fuel represents over 70% of your plant’s operating cost, even minor improvements in fineness and balance can generate significant savings. SAS modernization programs pay back quickly, while continuing to deliver long-term reductions in maintenance and emissions.

The result: improved plant reliability, optimized heat rate, and maximized profitability.

Consider a typical 500MW unit operating multiple MPS or CE style coal mills. By improving fineness, balancing fuel distribution, and reducing air leakage, the unit has the potential to see:

- $1.2–$2.0 million in annual fuel savings

- 2–3% improvement in boiler efficiency

- Reduced maintenance outages and component replacements

- Extended service intervals between rebuilds

In one major 700MW plant, seven MPS89 mills were modernized in under 10 days per unit.

The improvements were immediate: better fineness, lower amp draw, improved combustion stability, and higher throughput. Follow-up testing confirmed the modernization had paid for itself within the first quarter of operation

The program’s financial impact goes beyond efficiency. Plants also benefit from:

- Reduced NOx and CO emissions, lowering compliance costs.

- Improved reliability, minimizing forced outages.

- Enhanced load response, supporting flexible dispatch requirements in today’s dynamic grid.

These operational and financial gains make the SAS modernization program one of the fastest-returning investments available to coal-fired utilities.

The SAS Advantage: Engineered for Long-Term Value

Unlike piecemeal upgrades, SAS provides a complete, vertically integrated solution that is engineered, fabricated, and installed by one team.

Key advantages include:

- Proven Technology: Patented components validated in hundreds of installations across North America.

- Turnkey Execution: One vendor for design, manufacture, installation, and tuning.

- Material Superiority: SureAlloy®, Vanguard®, and CT-28 overlays extend component life beyond OEM standards.

- Rapid ROI: Fuel and efficiency savings typically offset project costs within one operating cycle.

- Made in the USA: All components and wear resistant materials are manufactured in the USA.

This combination of technical precision, field experience, and operational accountability has positioned SAS Global as a trusted partner for utilities seeking long-term performance and cost stability.

Why Modernization Matters Now

Many coal pulverizers / mills in today’s fleet are decades old. Some are operating far beyond their original design life. Component tolerances loosen, internal component wear has occurred, air leakage increases, and fuel fineness degrades over time.

Even when maintenance is performed, outdated designs often limit the achievable performance, trapping operators in a cycle of reactive repairs and declining efficiency.

Modernization offers a smarter, sustainable path forward:

- Retain existing assets: avoiding costly replacements or permitting challenges.

- Incorporate next-generation designs: leveraging SAS’s patented mill modernization components.

- Reduce downtime: with the utilization of premium wear resistant materials.

- Enhance compliance: through better fuel control and reduced emissions.

For utilities facing tight budgets and stringent performance targets, SAS’s modernization program provides a clear and achievable path to operational excellence and cost control.

SAS Global: Setting the Standard for Modernized Performance

SAS represents the next evolution in coal pulverizer modernization. Each SAS Modernized Mill integrates SAS patented components and premium wear resistant materials; from the Patented Rotating Vane Wheel and High Spin Classifier to the Silver Bullet Exhauster and Adjustable CV-Style Orifice.

The result is a mill that delivers peak combustion efficiency, balanced fuel flow, and unmatched reliability all without the cost or complexity of a new system.

SAS engineers tailor each modernization project to the customer’s specific goals:

- Efficiency-Focused Upgrades to improve fineness and heat rate.

- Capacity-Focused Upgrades to increase throughput.

- Maintenance-Focused Upgrades to extend component life and simplify rebuilds.

Each is fine-tuned through real-time diagnostic testing, ensuring it performs at or above specification from day one.

Field-Proven in Every Major Utility

SAS Global’s modernization systems are installed across dozens of North American power plants, from mid-sized municipal stations to 1,000MW baseload facilities.

Utilities rely on SAS for:

- MPS Mill Modernizations / Rebuilds

- MBF and IHI Mill Modernizations / Rebuilds

- CE HP, RP, RS, and RB Series Modernizations / Rebuilds

- Riley Ball Mill and Remote Classifier Modernizations

- EL Mill Modernizations / Rebuilds

- On-site tuning and performance validation

No two plants are identical, and SAS’s ability to

custom-engineer, manufacture, and install each modernization sets it apart as a uniquely capable partner in the power industry.

A Modern Solution for a Demanding Future

In an era defined by efficiency and environmental performance, maintaining legacy equipment is no longer enough.

SAS Global Corporation’s

Turnkey Pulverizer Modernization Program offers a clear path to

lower fuel costs, higher reliability, and faster ROI.

All while extending the life of existing assets.

By combining innovative engineering, proven materials, and turnkey execution, SAS helps power producers achieve the performance of a better-than-new system at a fraction of the cost.

The result: improved plant reliability, optimized heat rate, and maximized profitability.

Contact SAS Global for Your Modernization Evaluation