Maximize Combustion Efficiency: Why Coal Mill Inspections & Maintenance Can’t Be Ignored

Maximize Combustion Efficiency:

Why Coal Mill Inspections & Maintenance Can’t Be Ignored

In a coal-fired power plant, the pulverizer (or coal mill) is more than a “fuel delivery device.” It is a critical link in the combustion chain. Poor pulverizer performance ripples downstream: degraded combustion, higher unburned carbon, slagging, fouling, excessive emissions, fouling of downstream equipment, and ultimately, lost margin.

With over 60 years of experience working with coal-fired power plants, SAS has found that many units under-optimize their mills. They rely on scheduled overhauls or reactive fixes, rather than a disciplined, performance-driven inspection and maintenance regime paired with targeted modernization. The result: your mill rarely operates at the fineness, balance, and throughput required to deliver optimal boiler performance.

We will be discussing why you must inspect and maintain your coal mill proactively, how to structure that inspection/maintenance regime, and where modernization components can amplify the gains. All with a constant eye on combustion, efficiency, emissions, and slagging.

Why Pulverizer Performance Matters: The Combustion Link

1. Fineness, combustion, and heat rate

A properly operating mill must deliver coal fines to the boiler that are small enough for rapid, complete combustion.

Coarse particles burn slower, or not fully, leading to:

- Higher Loss on Ignition (LOI) or unburned carbon in ash

- Lower combustion efficiency

- Lower flame temperature stability or flame detachment

- Potential CO formation or local quenching

In many modern low-NOₓ environments, the targets might be > 75 % passing 200 mesh, and < 0.5 % retained on 50 mesh.

When fineness is maintained, more of the carbon is oxidized in the lower furnace, improving heat absorption, improving heat rate, and reducing fuel waste.

2. Fuel (pipe) balance and burner uniformity

Even if the mill produces acceptable fineness, if coal is not balanced among the fuel delivery pipes, some burners may be starved while others are overloaded. This creates flame instability, local quenching, and pockets of under- or over-oxidation. Proper fuel balance enables each burner to operate near its design stoichiometry, reducing excess oxygen, limiting CO peaks, and smoothing the flame front.

In a balanced system, you also gain flexibility in staging, turn down control, and load follow performance.

3. Impact on emissions, slagging, fouling

- NOₓ emissions: With consistent fineness and fuel balance, burner stoichiometry can be tightly controlled. Poor pulverizer performance forces excess air or uneven fuel/air mixing, increasing NOₓ formation.

- Slagging/fouling: Coarse particles or hot carbon “outliers” can impinge on superheater or furnace surfaces and lead to slag deposition or tube fouling. Worse combustion tends to shift flame zones and cause local hot spots.

- Carbon carryover & flyash LOI: Elevated unburned carbon means more carbon in ash, which can hamper downstream ash handling or emission control systems (e.g. ESP or fabric filters).

- Heat transfer & boiler efficiency: Slagging/fouling degrade heat transfer, requiring more fuel to maintain steam output.

A pulverizer in sub-par condition effectively forces you to “fight” downstream:

- More sootblowing

- Higher CO and NOX

- More boiler tuning

- Increased slagging

- Erosion corrosion risks

Key Inspection & Maintenance Focus Areas

To keep your pulverizer truly “in tune,” a combination of set inspection schedule, diagnostic measurement, and corrective maintenance is needed. Below is a suggested framework:

A. Performance-Driven Testing & Sampling

Relying on run-time hours or tons processed is insufficient. You must measure the output to gauge performance.

- Iso-kinetic coal sampling: To determine actual fineness and particle size distribution. This becomes your baseline to guide adjustments or maintenance.

- Dirty-air flow and velocity checks: Validate that your indicated PA flow matches measured. Mis-indicated primary air flow in the control room can hurt fineness control, cause reject issues, and possible accelerated mill component wear.

- Fuel flow and coal balance measurement: Track individual pipe flows; identify imbalances among pipes.

- Classifier performance / reject return checks: Ensure reject clearances, reject cone settings, and return paths are unobstructed.

Use these readings both during steady runs and after major overhauls to confirm whether the mill is performing as expected.

B. Mechanical & Wear Inspections

Certain physical elements of the mill degrade over time. Regular inspection helps you catch small issues before the cause larger problems.

- Grinding elements and liner condition

- Inspect grinding table, rolls / tires, vane wheel, air seal gaps: wear changes profiles and clearances, altering the grinding dynamics and airflow velocities.

- Replace or hard face worn grinding elements before excessive wear causes poor grinding or damage to the mill.

- SAS Global offers premium wear liners fabricated from SureAlloy® premium carbide overlay plate and grinding element hardfacing/rebuilds.

- Classifier & reject components

- Check classifier vane alignment, blade condition, blade synchronization, reject cone clearance, gap alignment, and actuation linkages.

- Verify reject-return ducting is free of blockages, and fine/return flows aren’t diverted or restricted.

- Springs, linkages, clearances

- Spring tensions on classifier actuation, mechanical linkages, and clearances must be measured and documented.

- Re-establish the as-designed OEM clearances after repairs or part replacement, do not just copy old settings blindly.

- Trunnion and bearing health, alignment

- Monitor bearing temperatures, vibration, alignment, rotational tolerances, and seals.

- Any eccentricity, misalignment or looseness can degrade pulverization uniformity or cause structural damage.

- Plenum, airflow seals, wear surfaces

- Inspect plenum and seal air systems. If seal air leaks or cracks occur, they disturb mill pressures and performance.

- Validate ducting integrity: leaks or holes in the primary air path reduce effective velocity or mis-bias airflow.

C. Adjustments, Tuning & Re-Validation

After you correct wear, make primary air adjustments, or change grinding pressure, always

re-test fineness, balance, and airflow before considering the unit “in spec.” It’s common to find that old classifier or air velocity settings are no longer optimal after component replacement.

How Modernization Components Multiply Your Gains

Even a well-maintained mill may not reach full design potential if it's still operating with the original OEM components. Modernization components give you the ability to handle different coal types, higher throughput demands per mill, and reach stricter emission targets.

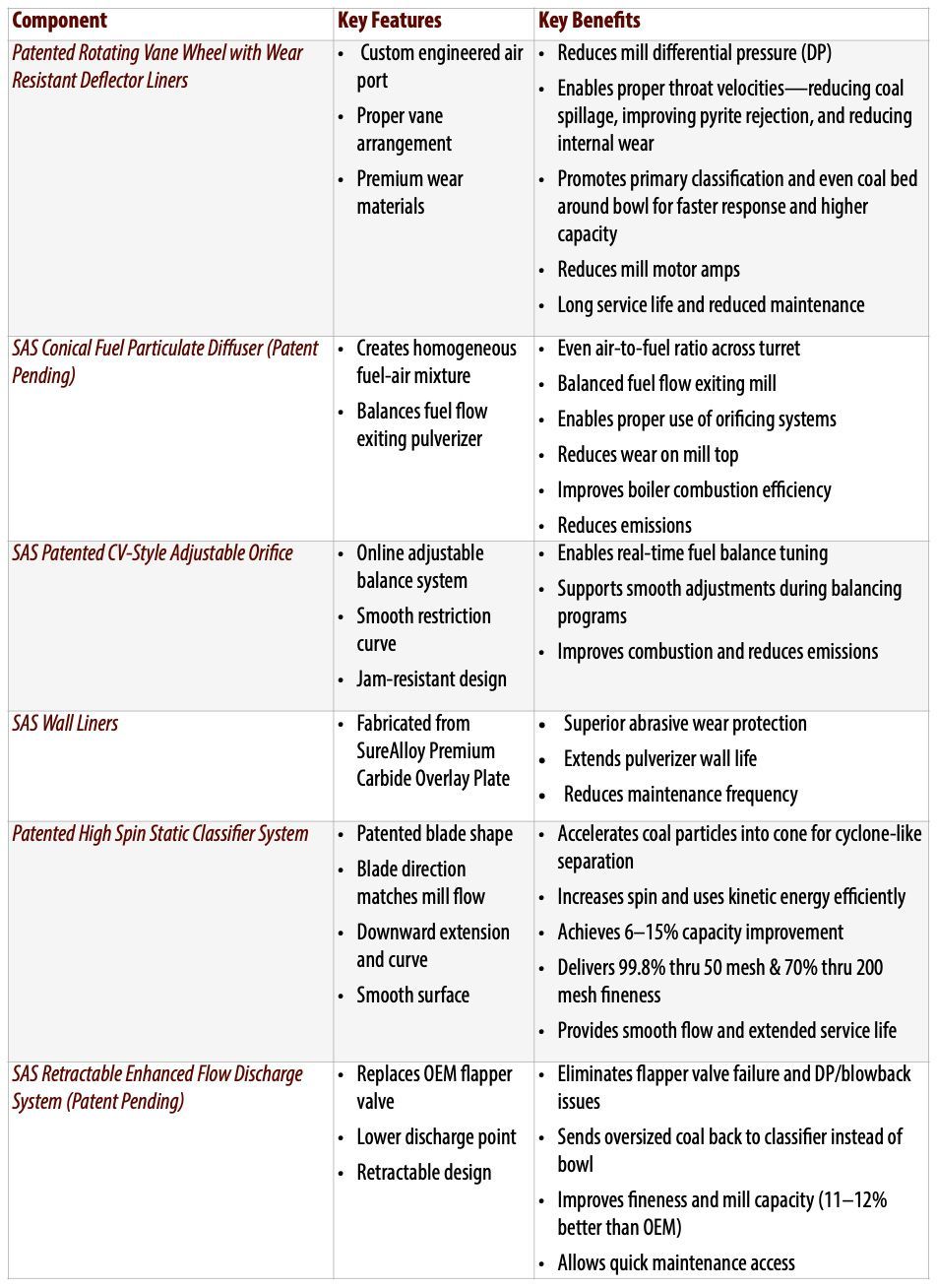

At SAS Global, we specialize in mill modernization components and services to help retrofit your pulverizers. Our components are designed specifically for MPS, IHI, CE, MBF, EL, Riley/ball mills, and more. Each component is not cookie-cutter; SAS engineers design it to your specific throughput, fuel, and emission targets.

Here’s how Mill Modernization works to improve the efficiency of your Facility:

Once the Modernization Components have been installed, the potential margin for improvement (throughput, fineness, fuel balance) increases. Meaning your inspection and maintenance efforts can yield even greater returns.

The SAS Turnkey Modernization approach includes baseline diagnostic testing, engineering & design, fabrication, installation, and combustion tuning following installation.

In fact, in one recent project, SAS reduced overhaul time per mill by 33% compared to prior work while integrating performance-enhancing components and saw measurable heat rate improvements after final tuning.

The Payoff: Efficiency, Emissions, and Reliability

Let’s enumerate how a disciplined inspection + maintenance + modernization program pays off:

| Benefit | Explanation | Impact on Plant |

|---|---|---|

| Lower heat rate / fuel savings | More complete combustion, less unburned carbon, better flame stability | Each 1% heat rate gain can translate to millions in fuel cost savings |

| Higher throughput | With modernization, mills can handle more tonnage at design fineness | Capacity headroom for load growth |

| Reduced emissions | Tighter combustion control reduces NOₓ, CO, unburned carbon, and particulate penalties | Easier permit compliance, less downstream burden |

| Less slagging / fouling | Fewer coarse or hot outliers means less deposition on boiler surfaces | Reduced cleaning, stable heat transfer |

| Extended component life / reduce unplanned outages | Wear kept in check, and modernization reduces stress on parts | Lower maintenance costs, fewer stoppages |

| Better load response & flexibility | Balanced mills respond more predictably to load swings | Better performance during transient load changes |

In many plants, the ROI on modernization plus disciplined maintenance is under two years. Especially given today’s fuel prices and emission constraints. SAS’s published case studies and analyses underscore that performance gains are not theoretical; they are measurable and consistent.

Tips for Putting a Program in Place

Here are practical tips for maintenance managers and engineers as you roll out or refine your pulverizer inspection program:

- Baseline before outage

Capture fineness, fuel balance, airflow, and classifier settings ahead of your next outage. Use that as your benchmark to compare “after-outage” performance. - Adopt a “performance-driven” maintenance mindset

Don’t just replace parts on a timetable. Let your performance metrics (fineness, LOI, fuel pipe balance) trigger maintenance. - Document as-designed settings

When you perform a mill overhaul, document ideal settings (classifier blade positions, clearances, linkages, spring tensions). Use those as a reference, not “whatever was last installed.” - Repeat testing / tuning

After each adjustment or repair, re-sample and validate. Sometimes, slight classifier tweaks or airflow corrections are needed to recover design fineness. - Track trends

Log fineness, LOI, balance, and temperature deviations over time. Track drift and identify gradual decline before it becomes a crisis. - Plan modernization upgrades on a roadmap

Even if you can’t retrofit every component at once, plan a phased modernization path (liners, classifier, diffuser, vane wheels, balancing technology) and align it with scheduled outages. - Engage combustion/boiler tuning in tandem

Pulverizer improvements should be paired with boiler tuning, flame condition, and burner settings to capture the full benefit. SAS offers combustion tuning services as part of its turnkey modernization offering. - Train operators and maintenance crews

Make sure staff understand the sensitivity: small shifts in the classifier or airflow can have big combustion effects. Encourage feedback and ownership.

The health of your boiler depends intimately on the health of the pulverizers. You cannot expect best-in-class boiler performance, emissions control, or fuel efficiency if your coal mill is underperforming; grinding coarse, unbalanced, or drifting out of OEM specifications.

But the good news is: the path to improvement is well understood and proven. With disciplined inspection, measurement, targeted maintenance, and chosen modernization upgrades, your mill can deliver the fineness, balance, throughput, and stability that your combustion system demands.

At SAS Global, we stand ready to help you audit, modernize, tune, and sustain your coal mills. Not just with individual parts, but with turnkey programs designed for measurable performance gains. When your mill operates as it should, your boiler rewards you with lower fuel costs, better emissions, and higher reliability.

If you’d like help assessing your pulverizers, exploring modernization options, or designing a maintenance strategy, let’s talk.