Mining Smarter:

Mining Smarter:

How One CAT 789 Haul Truck Proved the Value of the SAS SA1750CR Dovetail Liner System

Reducing downtime. Extending liner life. Lowering cost per ton.

These are the top priorities for maintenance managers and reliability engineers in today’s high-pressure mining environment. At SAS Global, we’re not just meeting these goals—we’re exceeding them.

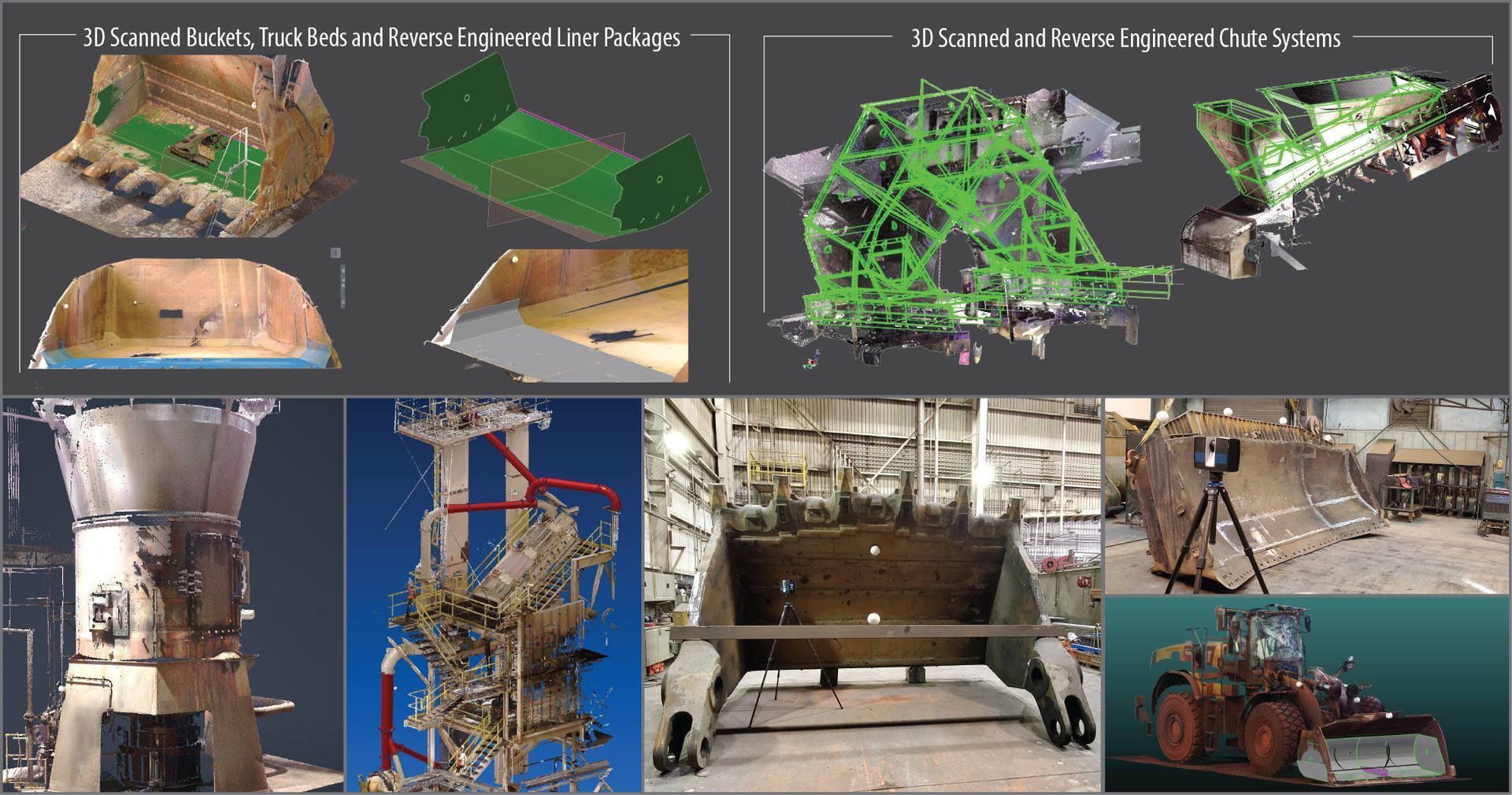

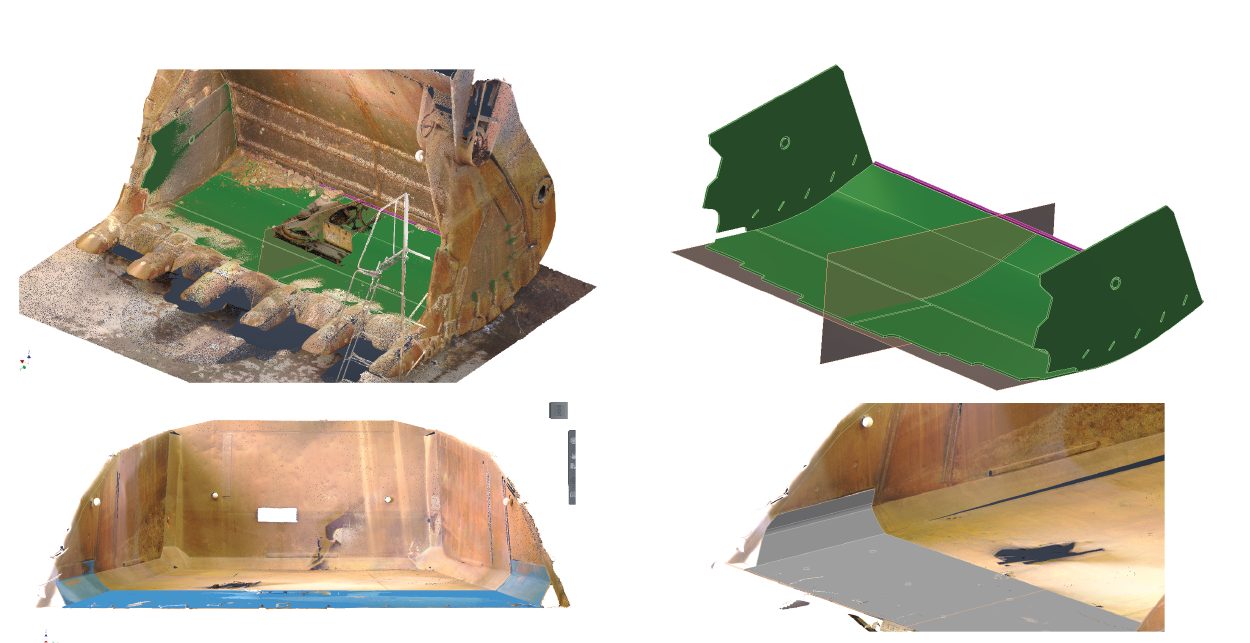

In this case study, we tracked the performance of our SA1750CR Dovetail Liner System installed in a CAT 789 haul truck and the results speak volumes.

Commissioned for Performance

In

November 2024, a CAT 789 truck at a major mining operation was outfitted with our

SA1750CR Premium Chromium Carbide Overlay Dovetail Liner. The liner started with a total thickness of

0.50 inches; composed of a

0.25" wear surface and

0.25" structural baseplate.

After just over 5 months and 3,102 hours of rigorous operation in high-abrasion conditions, we conducted a routine inspection. The results were impressive.

Inspection Findings

(April 2025)

| METRIC | VALUE |

|---|---|

| Operating Hours Since Installation | 3,102 hours |

| Remaining Overall Average Thickness | 0.465 Inches |

| SA1750CR Wear Surface Consumed | 0.035 inches |

| Percent of Wear Surface Consumed | Only 14% |

Projected Total Liner Life: Over 22,000 hours

That’s

2.5X longer than many conventional liner systems in similar service environments.

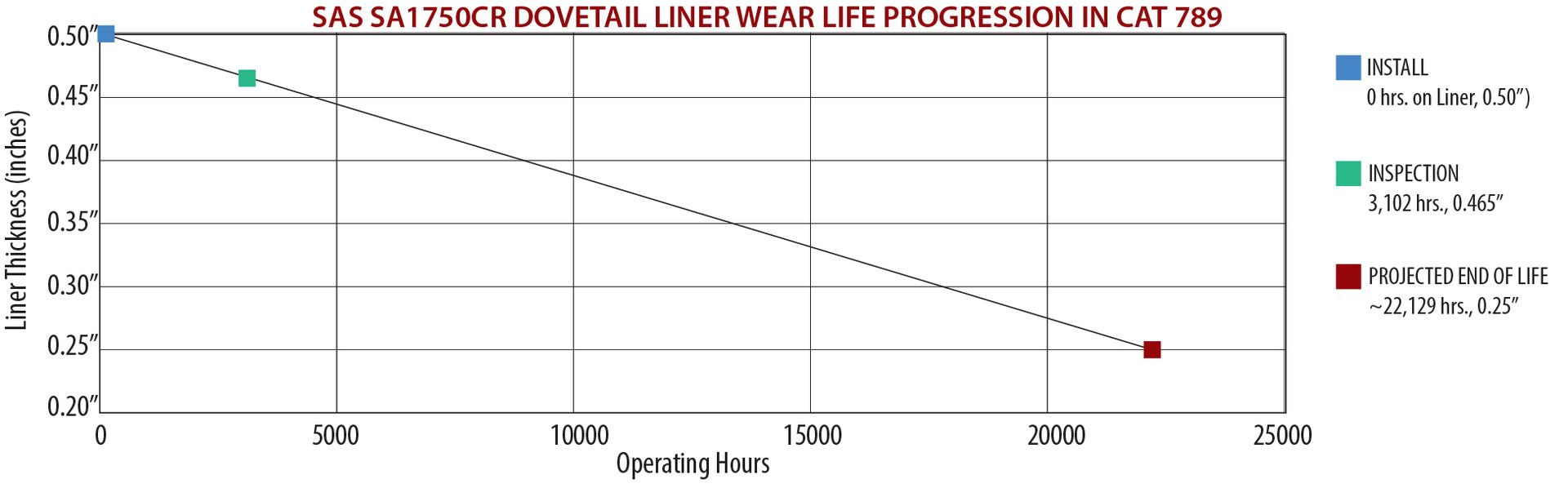

Visualizing the Performance

Wear Life Progression Chart

The SAS liner maintains a predictable and linear wear rate, making maintenance planning far easier and reducing unexpected changeouts.

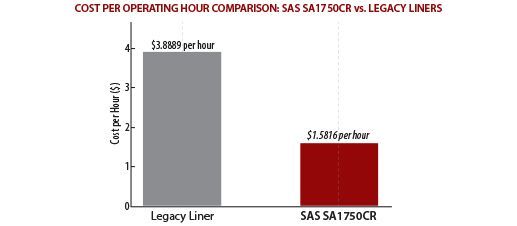

Cost Per Hour Comparison

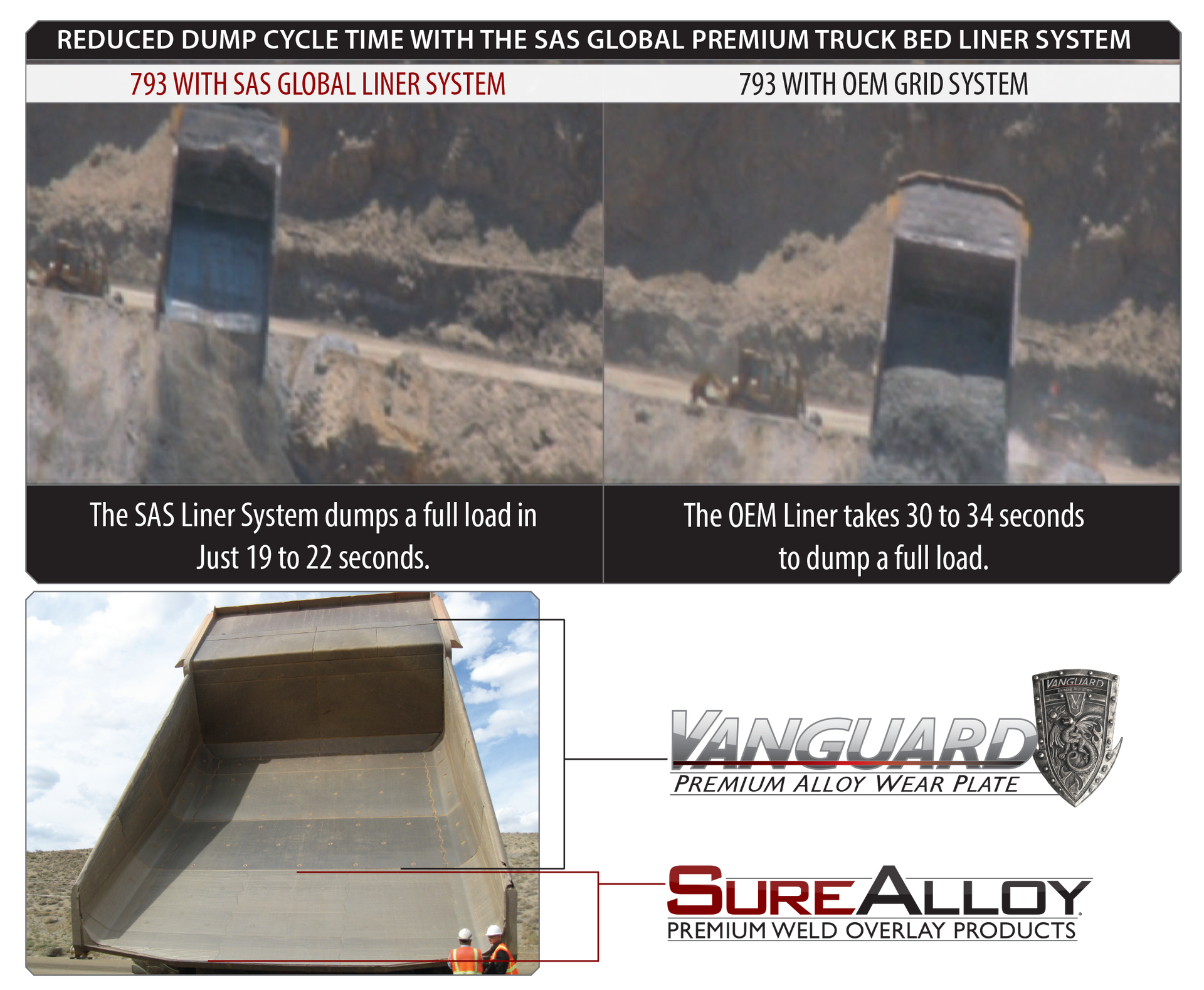

Here’s the cost savings comparison chart between the SAS SA1750CR liner and a traditional legacy liner system. It clearly shows:

- Legacy Liner: ~$0.00389/hour

- SAS SA1750CR: ~$0.00158/hour

That’s nearly 60% lower cost per operating hour with the SAS system — a powerful ROI argument for full fleet conversion.

Savings: 60% lower cost per operating hour

That’s substantial ROI delivered directly to your maintenance and operations budget.

Why Maintenance Managers Are Making the Switch

- Extended Service Life = fewer shutdowns and less manpower tied up in liner swaps

- Reduced Cost per Ton = better budget control and higher profitability

- Improved Safety = fewer changeouts means reduced exposure and faster turnarounds

- Predictable Wear Patterns = simplified scheduling and better use of planned maintenance windows

The SAS SA1750CR Liner Advantage

This is more than just a wear plate—it’s a fully engineered system designed for aggressive environments. The SA1750CR offers:

- Premium carbide microstructure optimized for extreme abrasion

- Consistent wear patterning for longer wear life and more predictable maintenance

Ready to Optimize Your Fleet?

If you're looking to:

- Extend liner life

- Reduce maintenance downtime

- Lower cost per hour

- Increase production uptime

Then it’s time to explore a full-fleet conversion to SAS Global’s SA1750CR Liner System.

We’re ready to help you assess your current liner performance and create a custom implementation strategy that improves your bottom line.