The Critical Role of Quality Control and Inspection in Heavy Metal Fabrication

Built to Last:

The Critical Role of Quality Control and Inspection in Heavy Metal Fabrication

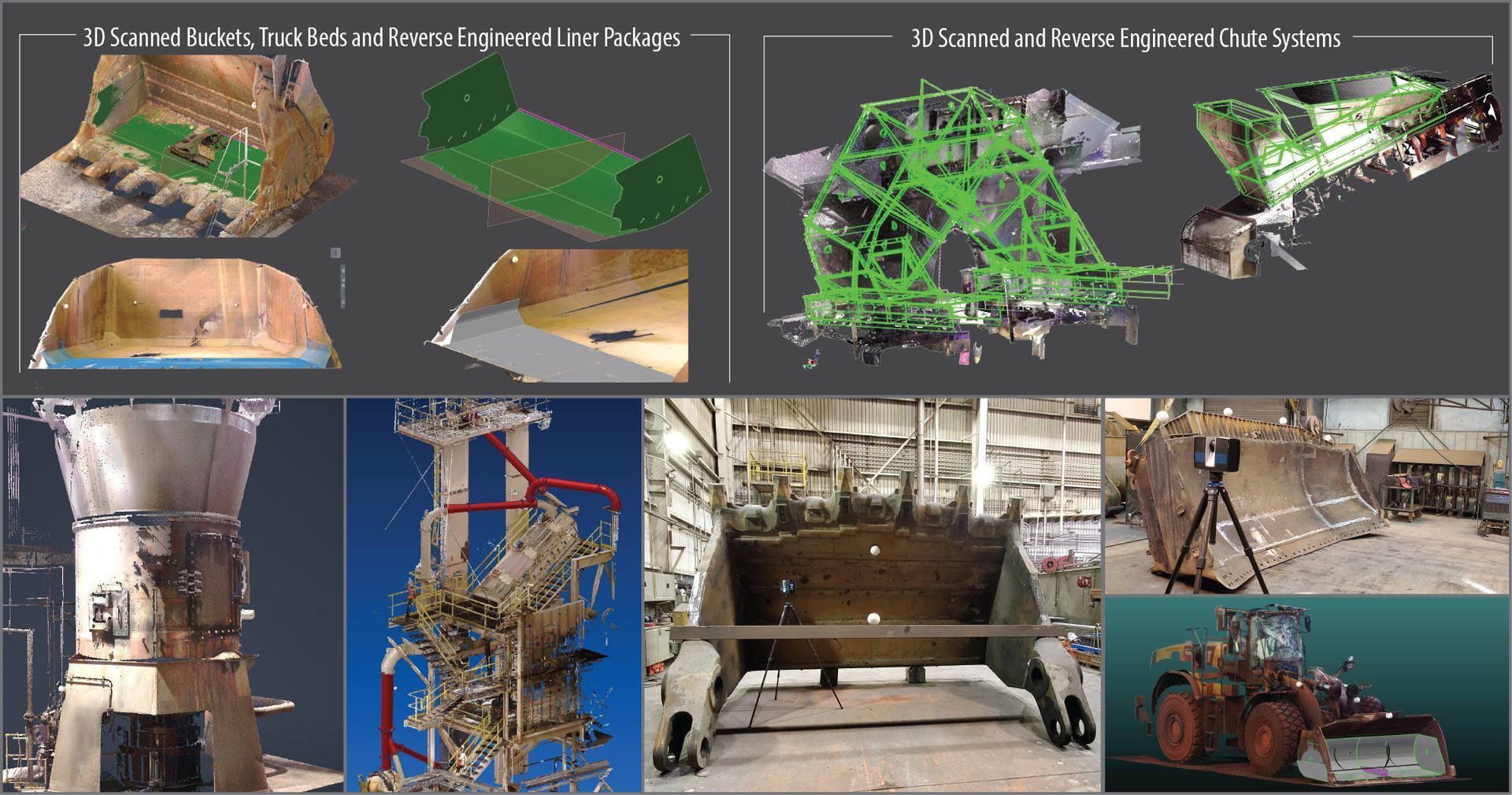

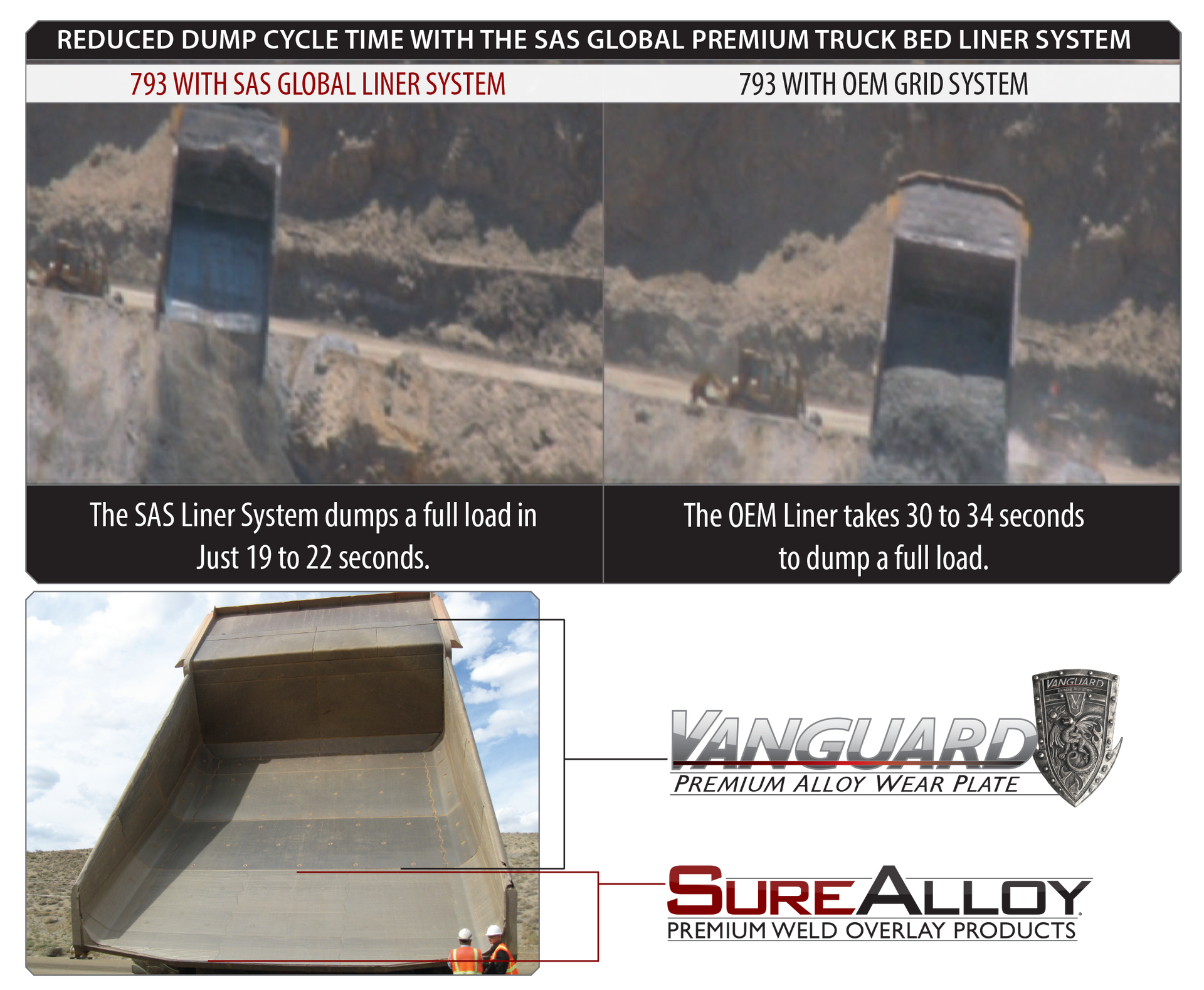

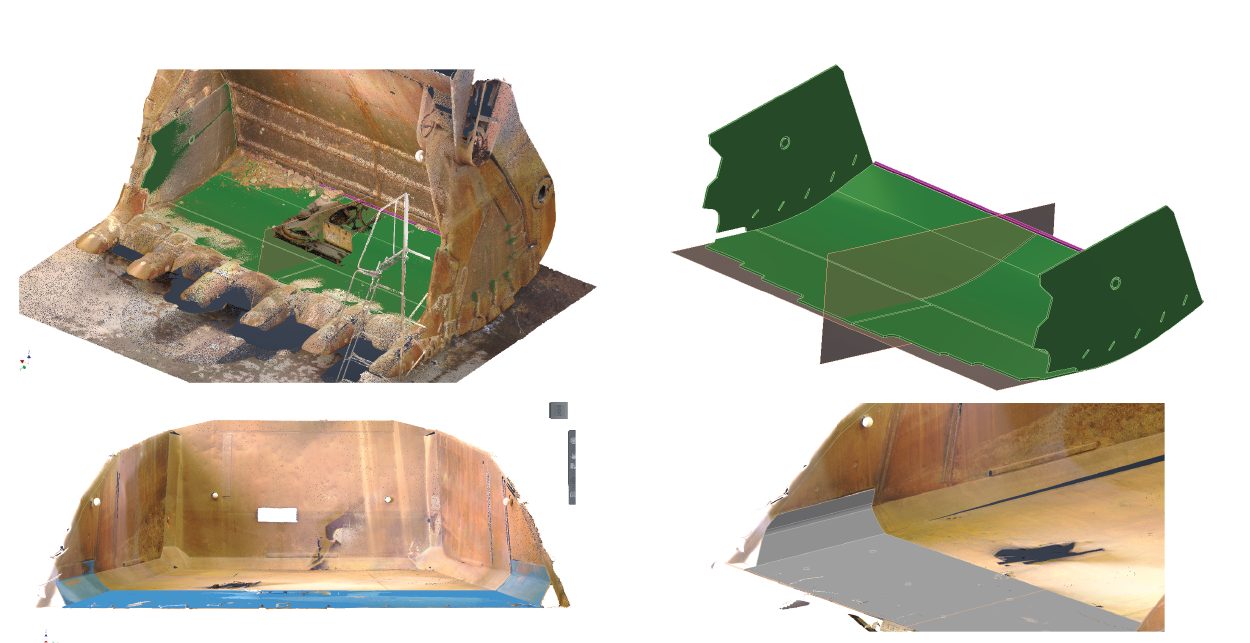

In the world of custom heavy metal fabrication, precision, durability, and consistency aren’t just desirable, they’re essential. Industries like Power Generation, Mining, Cement, Steel, Pulp & Paper, Asphalt, Aggregate, Glass, and Dredging demand fabricated components that can endure punishing environments, extreme wear, and non-stop production schedules. At SAS Global Corporation, we understand that achieving these requirements starts and ends with one unwavering principle: Quality Control.

Why Quality Control Is Non-Negotiable

Heavy industry facilities depend on large, complex components such as pulverizer housings, ductwork, mill parts, liners, chutes, and structural fabrications. These components must be fabricated to tight tolerances, properly welded, and built from materials that can handle abrasion, heat, and stress over extended periods.

Neglecting quality control in any of these stages—material verification, plate preparation, fit-up, weld integrity, dimensional accuracy, or final finish—can result in catastrophic component failure, unplanned downtime, safety hazards, and significant financial losses.

That’s why at SAS Global Corporation, we apply rigorous inspection standards throughout the entire fabrication process, ensuring that every part is manufactured right the first time.

The Value of an ISO 9001:2015 Certified Fabrication Facility

SAS Global Corporation proudly holds an ISO 9001:2015 certification, a globally recognized benchmark for quality management systems. But what does this mean for our customers?

It means:

- Traceable Processes: Every component—from wear liners to classifier cones—is tracked, inspected, and documented at every stage of production. Nothing is left to chance.

- Consistent Quality: ISO certification demands repeatability. You can expect the same high standard of workmanship whether you're ordering one part or a full system overhaul.

- Risk Mitigation: Through preventive action and nonconformance management, ISO 9001:2015 ensures issues are addressed before they become costly problems.

- Customer Confidence: Our customers in heavy industry sectors trust SAS because we deliver products that meet or exceed engineering specs—every single time.

- Continuous Improvement: ISO isn’t a static badge. It’s a commitment to constant evolution and improvement, from training programs to inspection tools to procedural enhancements.

The Importance of Proper Weld Inspection

Welding is often the backbone of fabricated components. At SAS, our welds don’t just look good—they’re built to hold under the harshest real-world conditions.

Weld inspections for:

- Structural integrity under dynamic and static loading

- Critical dimensions and tolerances

- Base material compatibility

- Heat-affected zones and proper weld penetration

- Surface finish and visual appearance

- Conformance to AWS D1.1 and job-specific standards

Our inspection process includes visual inspection, magnetic particle testing (MT), dye penetrant testing (PT), and ultrasonic testing (UT) depending on the application and project requirements.

Inspection at Every Stage – Not Just the End

Our fabrication quality doesn’t rely on one final inspection before shipping. Instead, we implement a stage-gate quality process:

- Material Verification – Incoming materials are inspected for chemistry, thickness, and conformance to customer specifications.

- Fit-Up Inspection – Critical dimensions and weld prep are verified before welding begins.

- In-Process Weld Inspection – Welds are checked during fabrication to prevent rework or structural issues.

- Dimensional Inspection – Templates, and calipers ensure accuracy throughout the build.

- Final Inspection – Each part is thoroughly reviewed, photographed, and documented before shipping.

This proactive approach protects our customers from delays, failures, and costly rework in the field.

Bottom Line: Quality Control = Customer Success

Whether you're operating a hard rock mine, dredging abrasive slurry, or managing a power plant, the fabricated components in your system are only as good as the

inspection processes behind them.

At SAS Global Corporation, we don’t just meet standards, we set them.

Our focus on

ISO-certified inspection procedures, certified welding, and decades of fabrication experience means you receive components that perform, last, and deliver maximum uptime.

Because when quality is built into every step,

reliability comes standard.

Contact SAS Global Corporation today to learn how our in-house fabrication and inspection processes can elevate the performance and longevity of your plant’s most critical components.