RapidFlow® Premium Smooth Surface Carbide Overlay Plate: Engineered for Superior Material Flow and Wear Protection

RapidFlow® Premium Smooth Surface Carbide Overlay Plate:

Engineered for Superior Material Flow and Wear Protection.

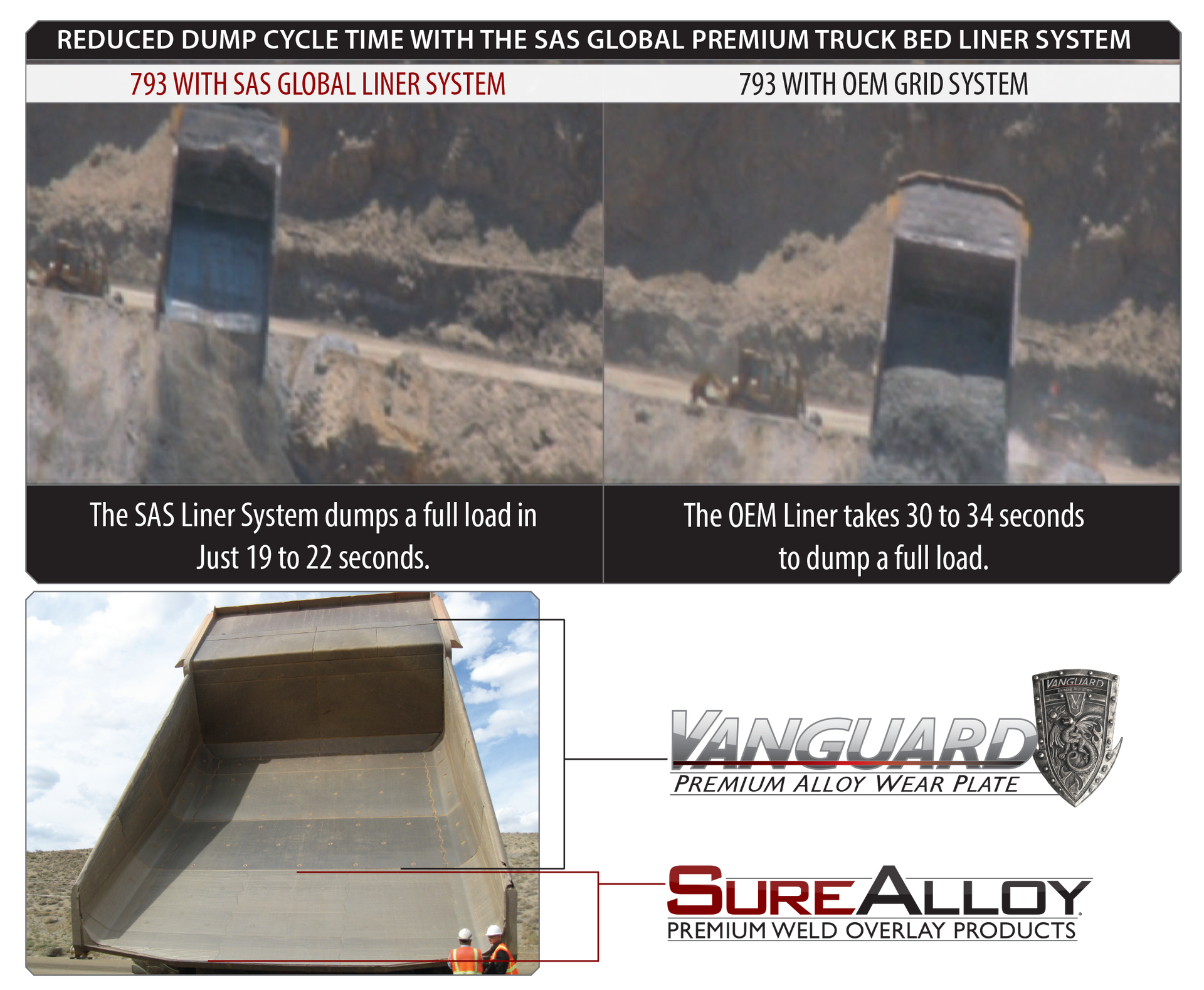

In bulk material handling, one of the most persistent challenges is balancing wear protection with consistent material flow. Traditional wear plates often create surface roughness that leads to material hang-up, plugging, and inconsistent discharge—causing downtime, cleanup costs, and lost production.

SAS Global Corporation’s RapidFlow® Premium Smooth Surface Carbide Overlay Plate solves this problem by combining the industry’s most advanced wear-resistant overlays with a precision-ground, smooth surface finish. The result: maximum protection against abrasion without sacrificing material flow.

Why Smooth Surface Matters in Wear Liners

Bulk solids such as coal, copper concentrate, cement raw mix, and ores have a natural tendency to stick, build up, or form ratholing in bins, chutes, and hoppers. Standard wear material surfaces can create drag and material hang-up.

Independent testing confirms that the

RapidFlow® finish significantly reduces wall friction, producing

flow characteristics better than stainless steel 304 2B finish—an industry benchmark for smoothness.

In real-world testing at coal-fired power stations and mining operations, RapidFlow has shown:

- Reduced chute and hopper blockages

- Improved flow in chutes with minimal flow angles

- Improved discharge consistency

- Lower downtime for cleaning and maintenance

- Extended equipment life by protecting against high wear zones

Backed by Independent Flow Testing

Laboratory flow property evaluations by Independent Companies provide strong evidence of RapidFlow’s performance:

- Wall friction and chute angle tests confirm that RapidFlow® SA1750CR and SA2000 grades deliver similar or better flow than stainless steel liners when handling coal.

- Dynamic Adhesion Drop Tests conducted with copper concentrate demonstrated that RapidFlow showed virtually no material build-up, averaging less than 0.1 g of adhesion per test, far outperforming other liners like TIVAR 88.

- RapidFlow’s surface roughness (Ra ≈ 0.2–0.3 µm) is smoother than most polymer liners and significantly smoother than standard carbide overlay finishes.

This means operators can rely on RapidFlow® not just for durability, but for predictable, reliable flow performance—even with cohesive or moist materials.

Available in All SureAlloy® Premium Grades

SAS Global manufactures RapidFlow® using its complete portfolio of SureAlloy® Premium Carbide Overlay Plates, ensuring a perfect fit for your specific application:

- SA1750CR – Premium Chromium Carbide Overlay Plate

- SA2000 – Premium Complex Carbide Overlay Plate

- SA6000 – Patented Micro-Structure Complex Carbide Overlay Plate

Where RapidFlow® Excels

RapidFlow® is the ideal choice for industries where material flow reliability is just as critical as wear resistance, including:

- Coal-fired and biomass power plants – preventing bunker and chute plugging

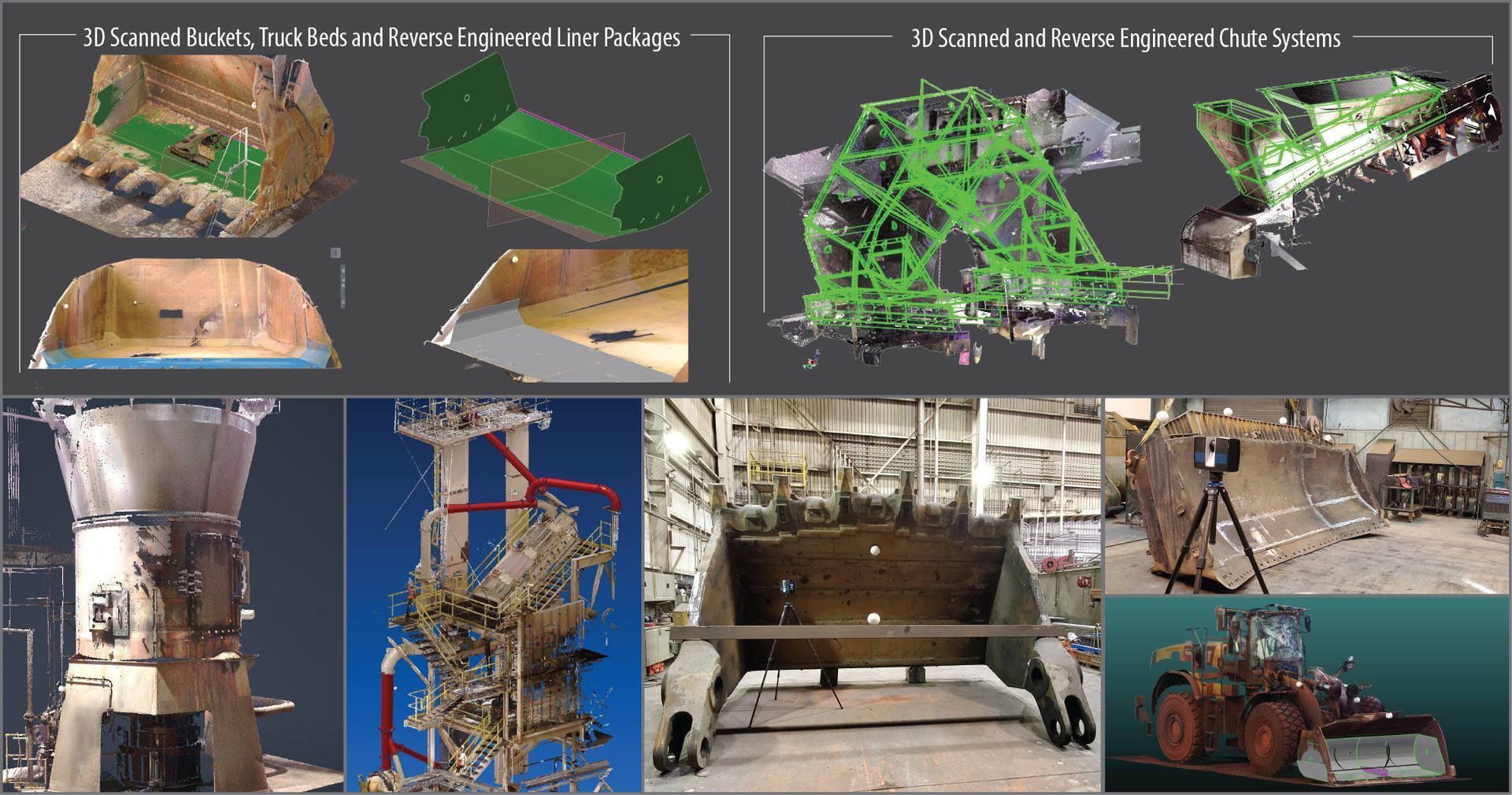

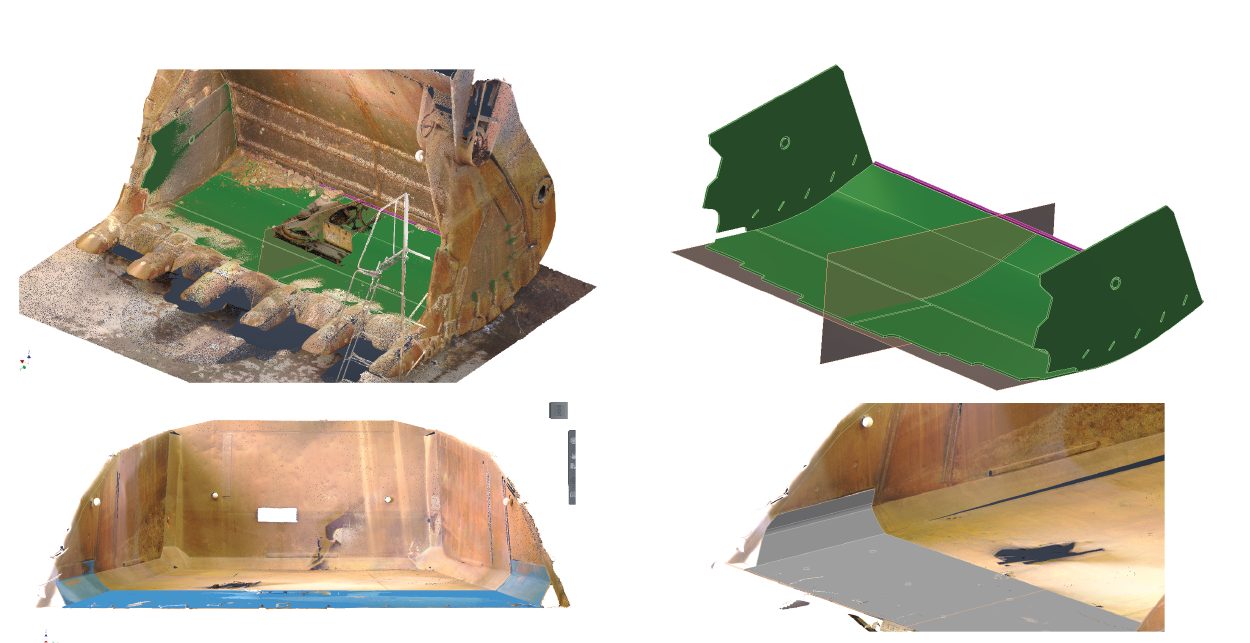

- Mining & mineral processing – ensuring consistent ore and concentrate handling

- Cement plants – reducing buildup in raw feed chutes and silos

- Steel and foundry operations – improving scrap and slag flow handling

- Ports and terminals – keeping shiploader and transfer chute systems operating smoothly

The RapidFlow® Premium Smooth Surface Carbide Overlay Plate is more than just a wear liner—it is a flow assurance solution. By eliminating the tradeoff between maximum wear resistance and smooth material handling, RapidFlow® ensures that your plant operates safely, efficiently, and with reduced maintenance costs.

Whether your challenge is abrasive wear, sticky material, or flow stoppages, RapidFlow® delivers the best of both worlds—superior wear life and reliable material movement.

Learn more about RapidFlow® and SAS Global’s complete SureAlloy® wear solutions at sasglobalcorp.com.