OTHER SAS FOUNDRY COMPONENTS

Engineered to Outlast | Built for Harsh Environments | Designed for OEM Compatibility

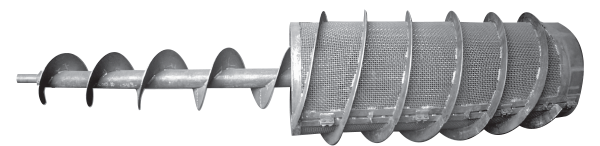

SCAPLING DRUMS

SAS Global manufactures premium-quality Scalping Drums engineered to outperform standard OEM designs in Wheelabrator®, Pangborn®, and other shot blast machines. Whether you need a brand-new drum or a cost-effective rebuild, SAS delivers custom solutions that maximize wear life and reduce long-term maintenance costs. Each drum is available in your choice of carbon steel, alloy steel, or 11–14% manganese steel, and can be upgraded with wear-resistant enhancements based on your application.

Why SAS Scalping Drums?

- Custom-Built to Your Specs – Designed for direct fit in Wheelabrator®, Pangborn®, and other OEM systems

- Premium Material Options – Choose from carbon steel, alloy steel, or high-manganese steel for superior wear resistance

- Operational Enhancements Available – Our engineers can recommend performance upgrades to reduce wear and extend service life

- Drum Rebuilding Services – Extend the life of your original equipment and save on replacement costs

- Made to Handle High-Abrasion Environments – Built for continuous use in shot blast systems with minimal maintenance downtime

Rebuild or Replace—We’ve Got You Covered

If your current scalping drum is worn but not beyond repair, SAS offers expert rebuild services to restore performance and extend component life. A rebuilt drum can deliver significant cost savings and help stretch maintenance budgets—without sacrificing quality or durability.

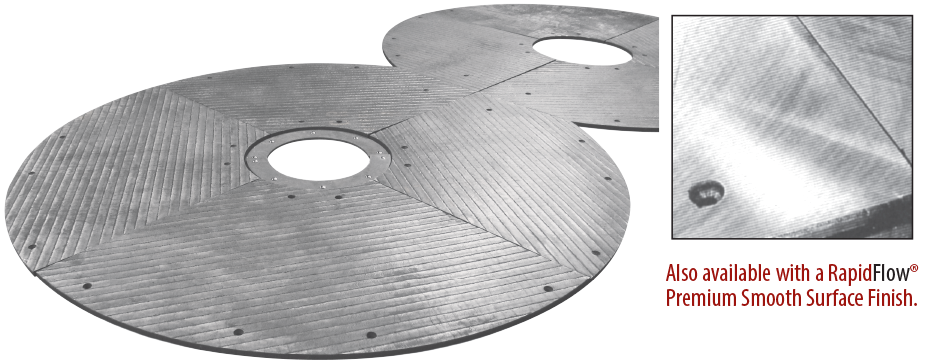

MULLER BOTTOMS - WEAR RESISTANT

SAS Global manufactures high-performance replacement muller bottoms that deliver exceptional wear resistance, precision fit, and significantly longer service life than standard OEM castings. Fabricated using SureAlloy® Premium Carbide Overlay Plate, these components are purpose-built for high-abrasion sand mixing environments—and can be installed in less than half the time of traditional cast bottoms.

Key Features & Benefits:

- SureAlloy® Wear Technology: Provides unmatched abrasion resistance and service life in sand mulling applications

- Precision Ground Top & Bottom Surfaces: Ensures a perfectly flat installation surface, consistent thickness, & accurate plow clearance

- Fast, Hassle-Free Installation: Outlasts OEM castings and installs in less than half the time

- Consistent Performance: Minimizes wear-related variability, keeping your mulling process reliable and efficient

- Guaranteed Fit: Machined and finished to exacting tolerances for drop-in replacement without modification

Why SAS Global Muller Bottoms?

- Reduce downtime with faster changeouts

- Cut long-term costs by replacing less often

- Maintain consistent sand quality with reliable fit and clearance

- Built with over 70 years of wear-resistant innovation